STCs for installations of modern, low-cost digital avionics suite expected by year’s end

July 23, 2017 – Dynon Avionics introduced its Dynon Certified line of integrated retrofit avionics systems for type-certificated GA aircraft at EAA AirVenture Oshkosh 2017, bringing a major avionics upgrade option to the market.

“For years, thousands of light-sport and amateur-built aircraft pilots have benefited from Dynon’s intuitive, affordable, and safety-enhancing integrated avionics systems,” said John Torode, founder and CEO of the Woodinville, Washington-based company. “We’re ready to bring the Dynon approach to the rest of the GA fleet.”

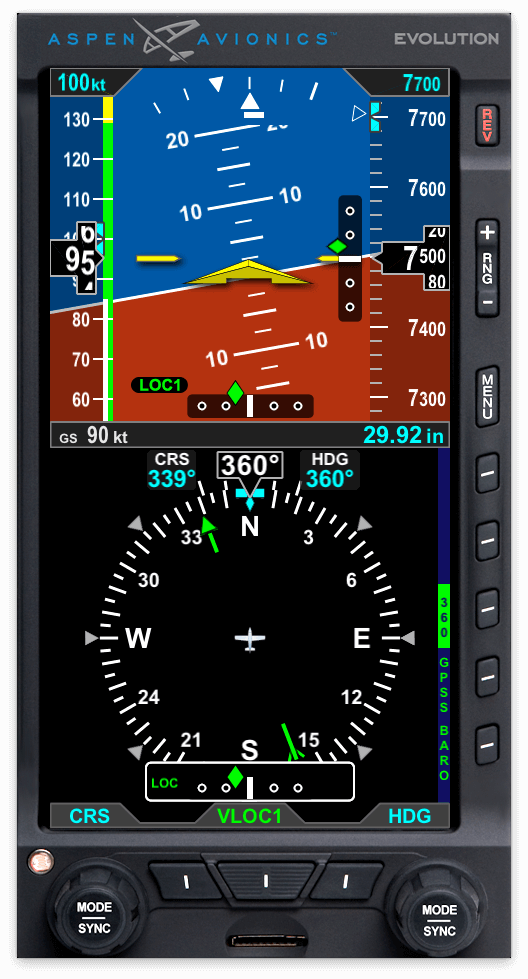

The Dynon Certified line features SkyView HDX, Dynon’s flagship integrated touch-screen avionics platform, providing primary flight display with synthetic vision and angle of attack, autopilot, engine monitor with all EGTs/CHTs, lean assist, and fuel computer. The line also includes a flight-planning mapping feature, ADS-B traffic and weather, an electronic flight bag, a Mode S transponder with 2020-compliant ADS-B “out,” and more. The touch screen can also be operated with ergonomic knobs and buttons, offering positive, intuitive controls for all flight conditions. Additionally, the system is compatible with popular IFR navigators like the Avidyne IFD series and the GTN/GNS series, and includes an independent backup EFIS.

At AirVenture, Dynon displayed a Cessna C172 and a Beechcraft B58 Baron with the new installations, a one-screen and three-screen suite, respectively. Both are currently awaiting STCs.

“There’s so much better situational awareness with a modern panel,” said the B58’s owner, Dave Forster of Friendswood, Texas, who replaced his legacy steam gauges with the SkyView HDX. “There’s no question as to what the airplane is doing or where you are.”

Dynon chose the two platforms to demonstrate the range of GA aircraft the SkyView HDX can accommodate, said Ian Jordan, the company’s chief systems architect.

Plans call for continuous expansion of the approved model list, with installations available through a Dynon direct installation center in the Seattle area, and through a network of approved facilities. Installations are expected to begin by year’s end, Ian said.

Dynon Certified products will be priced identically to the LSA/experimental versions, with STCs priced separately. Cost of the equipment installed in the initial C172 is approximately $16,000, and $2,000 for the STC. STCs for other aircraft will be scaled accordingly, but the company pledges to keep installations affordable.

To date, Dynon avionics have been installed in more than 20,000 such aircraft representing hundreds of platform types, according to the company. Dynon will continue developing and supporting products for its experimental aircraft customers, underscored by the four employee-owned experimental aircraft.

For more information, visit www.dynonavionics.com.