Industry leader also introduces “spherical” bearings, better door insulation

Industry leader also introduces “spherical” bearings, better door insulation

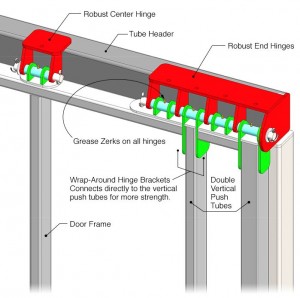

The engineering team at Schweiss Doors has developed an easy-to-grease hinge for its hydraulic doors.

The new hinge design with grease zerks on every hinge allows users to easily grease hinges from the underside of the doorframe without having to remove the top rubber weatherseal. The wrap-around hinge brackets connect directly to the vertical push tubes for added strength. Schweiss Doors doorframes are designed with double push tubes – unique to the industry – directly to the header tube. The advantage of double push tubes is that forces of the hydraulic cylinders are evenly distributed to the doorframe and the new wrap-around hinges. The double push tubes provide extra support against forces imposed by hydraulic cylinders used to open and close the door.

Schweiss Doors also has incorporated “spherical” bearings in all of its hydraulic one-piece doors. Spherical bearings are located at each end of the door’s power cylinders. Spherical bearing are critical to the safe and smooth operation of a hydraulic door, extending the life of the door.

The industry-leading bifold and hydraulic door manufacturer also introduced a better way to insulate its doors with new insulated panels. Cost-efficient and aesthetically appealing, these lightweight interior panels feature interlocking edges that fasten to the exterior of the doorframe, reducing installation time, while adding R-value and providing a fully insulated thermal barrier.

Schweiss Doors is the premier manufacturer of hydraulic and bi-fold lift-strap doors. Doors are custom made to any size for any type of new or existing building for architects and builders determined to do amazing things with their buildings, including the doors. For more information, visit www.bifold.com.