We asked Scott Sellers, co-host of the Paul New webinar to be held on May 7, why he would recommend the event to his peers. Here’s what he said.

By Scott Sellers

COO Author & 182RG Owner

To date, I’ve attended four courses delivered by Paul New, one for the Cardinal, one for the Skylane, one for my current 182RG, and a recent NAFI course.

Paul breaks down Cessna aircraft systems and simply describes how they function, strengths, weaknesses, and the preferred practice for operating those systems. You’ll come away knowing your Cessna measurably better than before and you’ll be better able to check your mechanics work after maintenance.

You will be better educated to determine your airplane’s airworthiness for your next flight. And you will have improved awareness of Go/No-Go Safety of Flight Items when deciding your airplane’s readiness/airworthiness for your next flight.

You will learn hundreds of important things in the live event with Paul New. It’s impossible to even make a list. But here are 15 interesting takeaways from previous events that can serve as examples.

- If it moves, lubricate it (see your aircraft’s lube chart).

- That is, except tracks or flap tracks (grease flap rollers only). There, lube only collects dirt, making for more difficult operations

- At run up pre-takeoff, straighten out the nose wheel to relieve stress on the system and hold the yoke rearward of neutral prior to engine run up.

- Start your engine at low rpm (1,000 or less) and do not exceed that until the oil temperature rises to at least 100° F. Smooth and easy throttle movements are preferred.

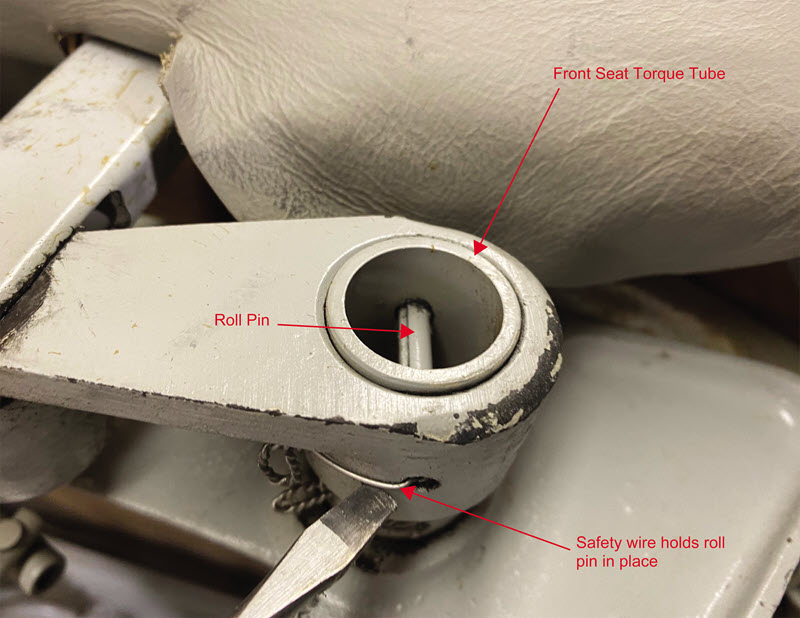

- Check seat torque tube roll pins for safety wire to protect against roll pin movement/failure. Note: None of our torque tubes roll pins were safety wired. See photo.

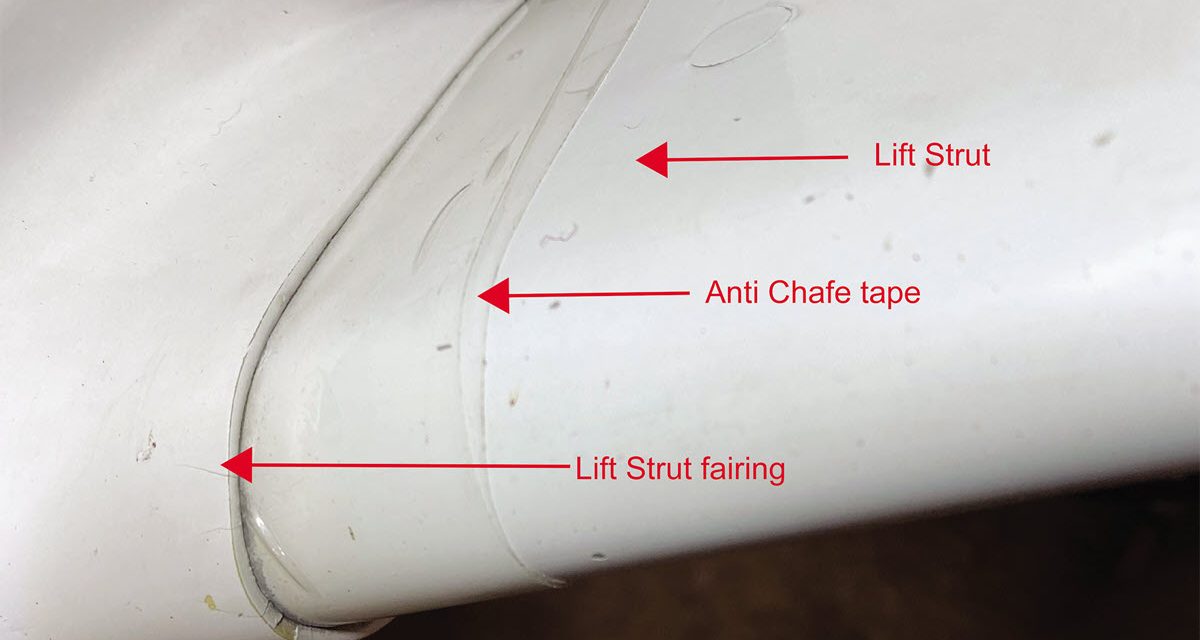

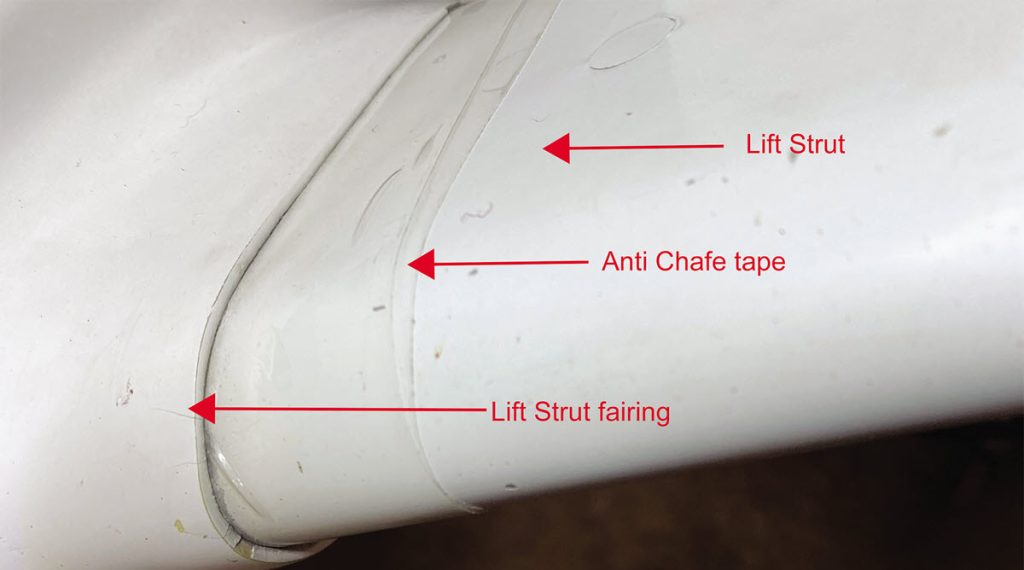

- Install anti-chafe tape at wing strut fairings to stop abrasion on strut. Note: Our airplane had no anti-chafe tape at strut fairings; most Cessnas do not. See photo.

- Over Square (MP higher than rpms) engine operation is preferred.

- Shock cooling(aircraft engines) is not a thing to be concerned about. There’s no data available to draw conclusions.

- You are human so will make mistakes operating your airplane. Give yourself the best chance to succeed on each flight. Religiously use resources like Checklists, available data, and published procedures.

6 More Tips for Retractable Owners

- Check gear actuator bolt torques at annual inspection. Replace with drilled bolts and safety wire installed per SNL86-49

- Add 5606 hydraulic fluid (separate small container) in hand pump with neoprene tube to travel tool kit. Put in Zip Lock. Use to fill gear and brake reservoir at preflight as needed while traveling.

- Paint red stripe on shimmy damper collar to strut to monitor that shimmy damper clamp is not moving on nose strut.

- Mark nose wheel turn limits on strut. Use red touch up paint.

- If there is any nosewheel shimmy, repair immediately. No further flight ops until shimmy is repaired.

- Include cleaning the hydraulic pump screen in your annual inspection. Note: Have replacement O ring on hand prior to removing screen as shown in figure 5-3 Hydraulic Power Pack Assembly on page 5-14 of the R182 and TR182 Service Manual.

You will learn hundreds of important things in the live event with Paul New. It’s impossible to even make a list. But here are five interesting takeaways from previous events that can serve as examples.

Save thousands by spending $300 — buy today and watch today.

Click on a photo for a popup.