By Elizabeth Gibbs

As owners of legacy Cessnas, many of us are all too familiar with an airplane’s biggest nemesis: corrosion. While many causes of corrosion are natural, some can be due to things that were installed in the airplane at the factory all those years ago.

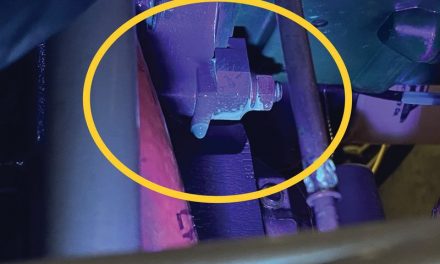

One such item, as pointed out by Paul New in the first topic of his 4-plus-hour online webinar on May 7, is the black vibration dampening panels that are found all over Cessnas built in the 60’s and 70’s. “These panels which are all over your single engine Cessna. They’re in the belly, on the sidewalls. They are basically a lead panel. They’re flexible, but they’re glued to the skin to keep the skin from vibrating,” described New.

He went on to add, “All that is really great, except they found out many years later that the glue they used is hydroscopic, so you have all this corrosion that occurs underneath.” Hydroscopic meaning “readily taking up and retaining moisture,” which is very bad news for aluminum skins.

So if you are the current owner of an older Cessna, or looking to purchase one, what do you do if you come across one of these black panels on the inside of your airplane? According to New, “If they’re in place, they’re fine. But you want to use a corrosion inhibiting compound frequently to keep them that way.”

He also notes that you can spend hours attempting to clean them off if you want to, but if they are really stuck on there, it’s going to be tough.

“If they’re not stuck, or if they’re lifting, the reason is not because the glue let go, but because the aluminum that the glue is attached to has started to corrode, and so the aluminum separates. That means you’ve lost aluminum from the skin. You don’t get to lose very much. The aluminum side skins are either 0.025 inch or 0.032 inch thick. There’s a bulletin that tells us how much we can lose. Generally, for structures you can lose 10% of the thickness of the piece of structure.”

“For Cessnas, on these open skins you can lose up to 20%.” But just how much material is that? To give a reference, New continues, “Well, 20% of 0.032 inch, that’s just over 0.006 inch. A sheet of paper is just under 0.003 inches. So two or three sheets of paper, that’s all you get to lose.”

It doesn’t take much before you’re in for some expensive repairs. Treating the area around these panels with a corrosion inhibiting compound such as Corrosion X or ACF-50, or removing and cleaning anything that is peeling off could save you a huge bill with your mechanic. “This prevention could save you a huge repair of replacing a skin or bonding on some sort of reinforcement.”

And the best news of all? “You don’t even have to talk to your mechanic about this stuff. You can just start opening panels and see what’s behind it.”