What to Know Before You Go

What to Know Before You Go

Sponsored by AirMart, Inc. – www.AirMart.com

The Right (and Wrong) Way to Rig a Crooked Flying Airplane

As a professional pilot and mechanic, I’m often asked to inspect and ferry airplanes from all over the country. With so many makes, models, and years of airplanes out there, you can never predict what kind of idiosyncrasies you might encounter.

Recently, I had a similar experience in two completely different airplanes. In both situations, I had completed a thorough preflight inspection, but very quickly into the flight home I noticed that the planes didn’t fly straight. One of these planes was an American Champion Scout. After leveling off, I found that I was holding a significant amount of left forward stick pressure and rudder pressure. In fact, it was so severe that I started to think I may have left my jacket wrapped around the horizontal stabilizer. I decided it was a good idea to head for the nearest airport and check it out. Well, there was no jacket on the horizontal and everything on the plane looked okay, so I bent the rudder tab some, climbed back into the cockpit, and flew (nearly 5 hours) the rest of the way home. It was miserable and my arm cramped the whole next day!

A very similar thing happened just a few weeks later in a 1999 Cessna 172. Fortunately, I had the KAP140 autopilot to do most of the work, but I still had to hold rudder pressure the whole time.

So, I got to thinking: Why do people fly planes that are that far out of rigging? It just doesn’t make sense! Do some pilots just not realize that crooked-flying planes can be fixed? Now granted, there is a right way and a wrong way to fix a plane that flies crooked and wing heavy. Unfortunately, all too often technicians attempt “quick fixes” that only make the problem worse and, ironically, don’t turn out to be such “quick fixes” after all.

What To Do If Your Cessna Is Slow

First, let’s take a look at the wrong way to fix a crooked flying airplane.

With a heavy wing (the plane wants to roll one direction), the pilot must keep a constant pressure on the ailerons to keep the wings level. This induces an adverse yaw that then requires a constant pressure on one rudder pedal to keep the nose straight. Often, pilots will blame the problem on the rudder trim and attempt to fix the problem by bending the rudder tab. After bending the tab over 45 degrees, they no longer have to hold constant rudder, but the heavy wing is still there.

The next “fix” they try is to adjust the push rod on one aileron. For example, if the left wing is heavy, the technician will adjust the left push rod so that the aileron is lowered into the slipstream. With the left aileron down and the right aileron streamlined, the hope is that this adjustment will add lift to the left wing. BUT, that’s not what happens. Remember, the goal is to fly wings level—without the pilot touching the control yoke. Once he lets go of the yoke, the slipstream over the wing will equalize the left and right ailerons. The left aileron will be pushed up by the wind, which, in turn, lowers the right aileron and turns the yoke to the left. Now you’re left with a real mess. When the pilot takes his hands off the yoke, both ailerons will droop an equal amount into the slipstream and the yoke will be off-center. And guess what? The left wing will still be just as heavy! So please, always keep the ailerons rigged correctly and symmetric with each other—you can’t fix a heavy wing just by tweaking the aileron rigging.

Now, let’s look at the correct way to make a plane fly straight.

First, verify that the ailerons are rigged correctly per the maintenance manual. Then take a close look at the flaps: it is possible to rig them unequally. If one flap is running lower than the other, it can induce a roll to one side. They’re easily checked with an inclinometer and, if found to be different, the entire flap rigging process in the manual should be followed. Don’t forget to check the rudder rigging too. The springs and steering bungees should center the rudder when the nose gear is off the ground. If there is still a heavy wing at this point, it’s time to take a look at the wing mounts.

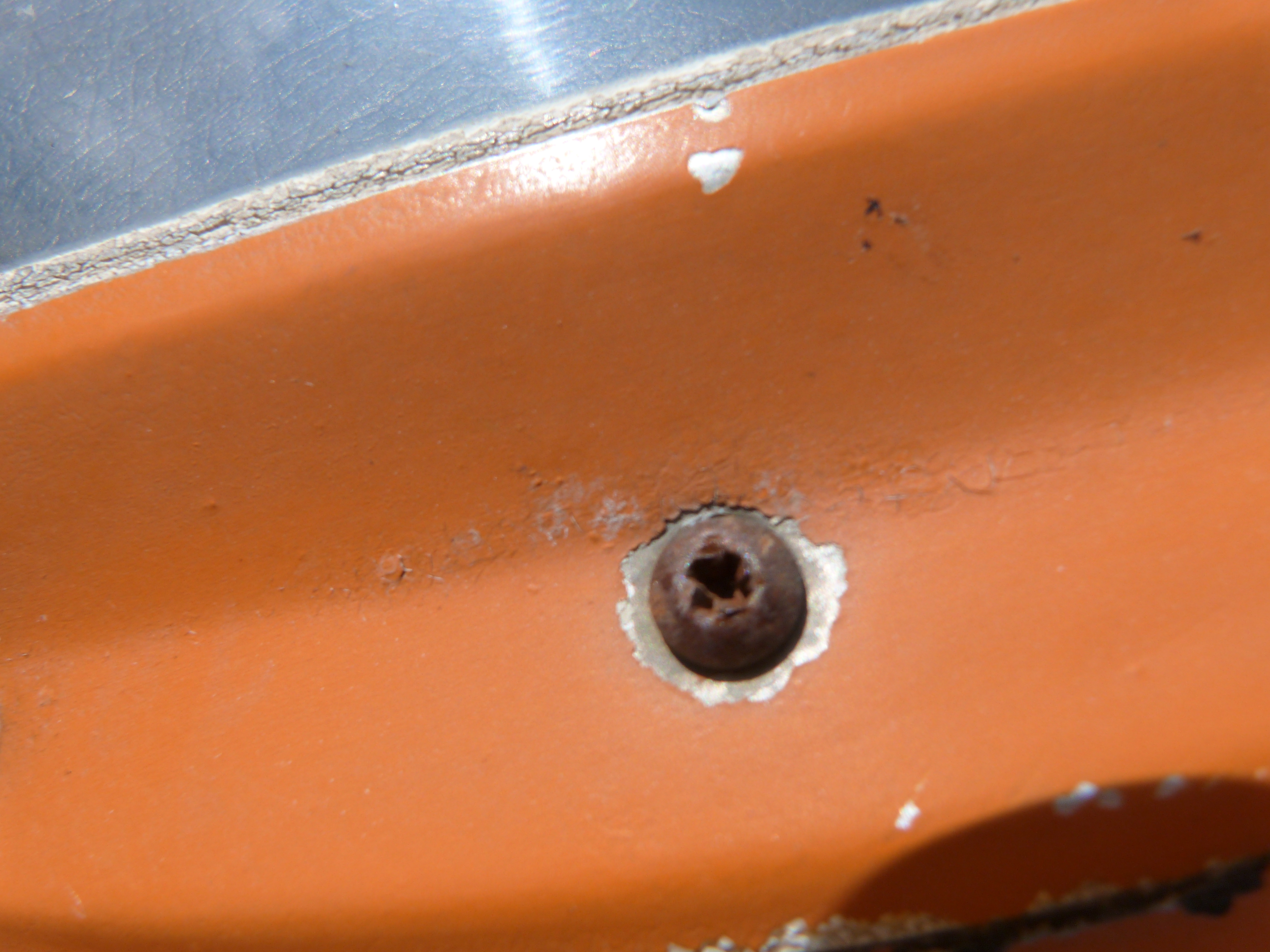

Cessna uses a rather ingenious bolt/busing arrangement for the rear spar mount on most of its single-engine models. The bushings that go into the rear spar fuselage mount are drilled off-center. With the mounting bolt loosened, the technician can rotate the bushing which, in turn, raises or lowers the rear wing spar.

Using our example above, if the plane has a heavy left wing the left wing eccentric bushing can be rotated to lower the rear spar. This increases the wing’s angle of incidence and angle of attack, thereby increasing the lift on that wing. It may take several adjustments and test flights to get it flying hands-off-level, but it’s worth the effort. Once the roll issue is solved, the rudder trim tab can be adjusted so the turn coordinator ball is centered during cruise flight. At this point, the pilot should be able to remove his hands and feet from the controls and the wings should remain level. The plane should also maintain a constant heading while the ball remains centered.

So, if you are a pilot who has just “gotten used to” holding left (or right) aileron pressure all the time, you don’t have to keep doing this. It isn’t that difficult for your maintenance shop to adjust the wing mount bushings. But, yes, this should ONLY be done by an A&P.