Most of us leave the wrenching of our aircraft to the guy or gal with A&P after their name. Sometimes, though, you can fix an issue yourself. One of the skills that you may need to do that is installing safety wire.

Know that you’re on solid legal ground here. FAR Part 43 Appendix A allows you to replace a safety wire if you need to. However, if you don’t have safety wire or the right tool, you’re in trouble. And if you have the right tool but don’t have the skill or knowledge to do it, you’re still in trouble.

First, you’ll need a spool of safety wire. I would recommend .032-inch stainless steel. This is available from Aircraft Spruce and other sources for about $9 for a 1-pound spool. This is a lifetime supply so purchase this and keep it with your aircraft tools in your baggage compartment.

Second, you’ll need safety wire pliers. These are also available from Aircraft Spruce for $24.95 for the 9-inch version.

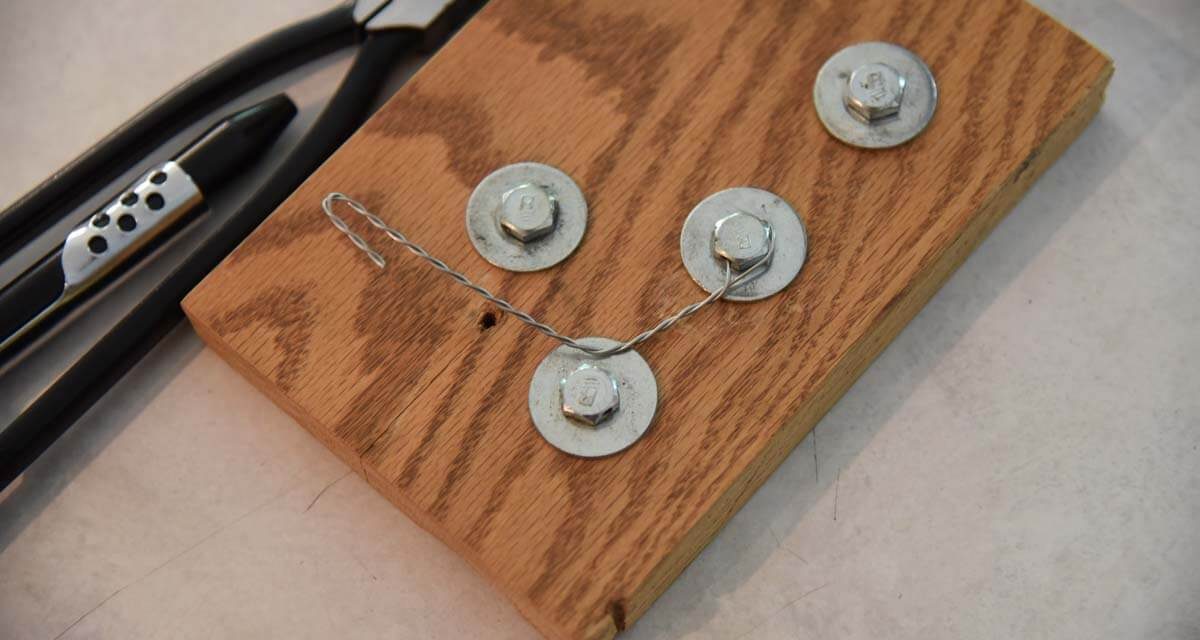

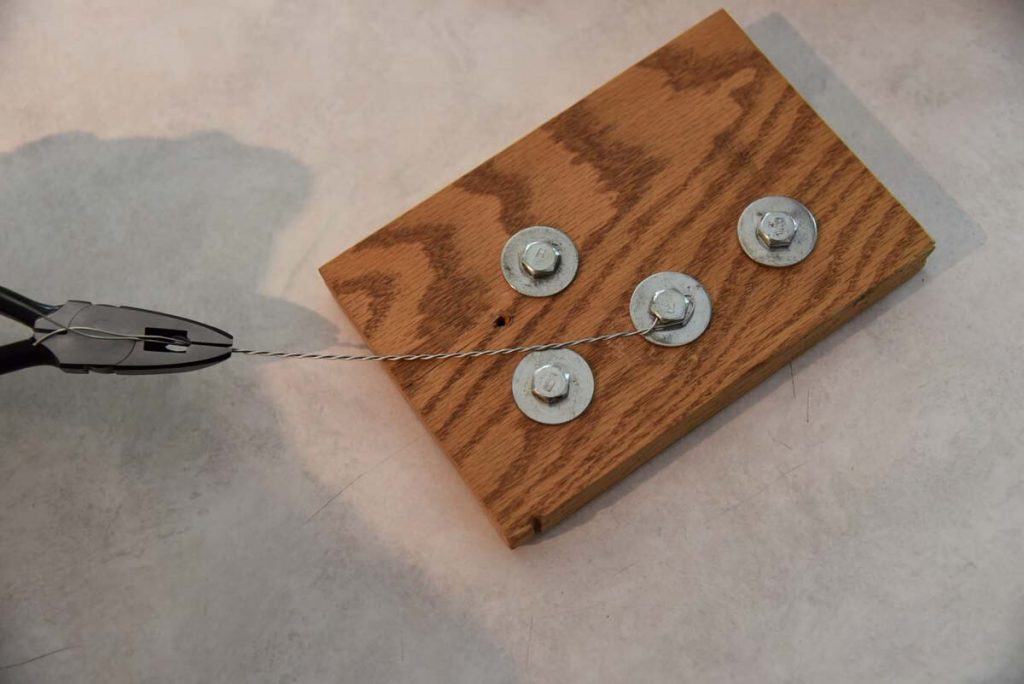

Third, you’ll need the skill to install a safety wire. This will take a little practice, which you can do in your hangar. I made a training device that I used to teach myself. You’ll need a few bolts with the safety wire hole in them. I put them in a small wooden board to practice on.

So how do you actually put on a safety wire?

AVweb’s December 2005 article by Kim Santerre entitled “Safety Wire Techniques” provides an excellent explanation.

“To do simple wiring tasks such as oil filters, just practice ahead of time at home using a vise to hold practice objects to get the basic feel of making twists with six to eight turns per inch. If you make more twists in the wire, then the wire hardens and becomes very brittle, which makes it easy to snap broken,” Kim wrote. “Remember to safety the wire from the oil filter to a tie point that will move in unison with the oil filter so the wire will not snap under engine movement or vibration. … Lastly, remember to make a ‘pigtail’ at the end of the wire, because an exposed wire end acts like a knife to lacerate hands and arms later reaching into the engine compartment.”

Using the pliers to do the safety wire twist isn’t hard and if you haven’t done one before, it’s actually fun! Practice it a few times on your training board and ask your mechanic for some instruction if you’re not quite getting it or if the safety wiring is more complex involving multiple connections. They’ll show you and you can practice some more. In five or 10 minutes you will be a pro!