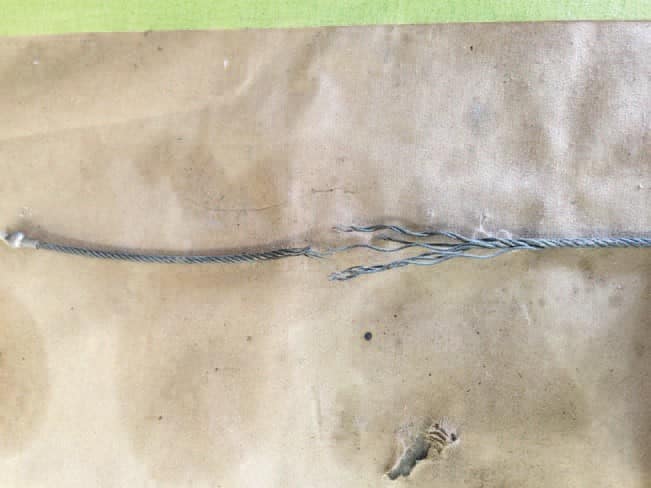

Your A&P should have already alerted you to this, Cessna Owner Organization webinar host Paul New was writing about it years ago, and now the FAA has reminded you again: Cables need proper inspection or you can miss the fact that they are frayed.

The FAA recently issued a Special Airworthiness Information Bulletin (SAIB) “intended to remind owners and operators of any airplane with cable-driven flight controls of the importance of adhering to existing inspection procedures in the applicable maintenance or shop manuals.”

In summary, the FAA received a recent report of a failed flap extend cable, and found numerous similar instances of a service difficulty report (SDR) over the past 20 years.

From the SAIB:

If the cable is not properly inspected, it can appear to be acceptable when it really is not. This SAIB focuses on the condition of the flap extend cables as they route around pulleys on all Textron Aviation, Inc. (formerly Cessna) 310, 310A, 310B, 310C, 310D, 310E, 310F, 310G, 310H, 310I, 310J, 310J-1, 310K, 310L, 310N, 310P, 310Q, 310R, 320, 320-1, 320A, 320B, 320C, 320D, 320E, 320F, 321, 335, 336, 337, 337A, 337B, 337C, 337D, 337E, 337F, 337G, 337H, 340, 340A, 401, 401A, 401B, 402, 402A, 402B, 402C, 411, 411A, 414, 414A, 421, 421A, 421B, 421C, and 425 airplanes. However, it also applies to the entire flight control system on any airplane model with cable-driven flight controls. Inadequate inspection of the flight control cables may result in undetected wear and/or corrosion that could lead to cable failure.

There are numerous sources for advice related to proper cable inspection, including this popular YouTube video.

The topic is not new; in fact, Tennessee Aircraft Services owner Paul New wrote about the topic in 2015. From his website:

The control cables in our Cessnas are manufactured using stainless steel or galvanized steel cable. Each material has its own advantages and disadvantages. Stainless is more resistant to corrosion but wears faster due to internal friction between cable strands. This internal wear is difficult to detect during routine inspections. Galvanized steel cables wear better than stainless and are easier to inspect for corrosion problems. However, they don’t last long in corrosive environments.

The most common inspection method is simple visual inspection. A next level up is to pull a cotton cloth along the cable which will snag on any broken outer strand. The most common area for damage is any area that bends around a pulley, so more attention should be focused there. Due to the stainless cable tendency to wear internally, the best way to inspect it is to relieve all tension, then slightly untwist it. Obviously, not a practical inspection to perform at every annual. FAA AC 43.131B change 1 chapter 7 section 8 paragraph 7149 gives great detail for various cable inspection methods.

Topics like this will be covered in the April 9 event with Paul New and Scott Sellers. Learn more about Paul New and his webinar for Cessna owners here.

You can learn more about this topic in the full article that Paul New wrote. Read that entire article on the Tennessee Aircraft Services website, here.

Regarding the SAIB, you can click here to download this SAIB.