By Rocky Landsverk

AWI (Aerospace Welding Minneapolis, Inc.) and Acorn Welding of Edmonton, Canada, have merged under the roof of Hartzell Aerospace Welding, creating a one-stop shop for owners of legacy Cessna and Piper planes to source all their exhaust, engine mounts, and air box needs.

Aerospace Welding and Acorn are a part of Hartzell Aviation, which is the umbrella holding company for Hartzell Propeller, Hartzell Engine Tech (H.E.T.), and Quality Aircraft Accessories (QAA). A press conference was held at AirVenture 2022 in Oshkosh to announce the rebranding of these companies now operating as one unified group.

“The Hartzell Aviation umbrella brings together an outstanding array of firewall-forward products. The creation of Hartzell Aviation reinforces the three organizations’ core competencies and their joint pursuit of improving General Aviation,” states a press release.

What it means for pilots is that if (well … when) you need a new exhaust part, your mechanic will likely be dealing with AWI, which has relationships with virtually every mechanic and shop in the US, and now with the merger of Acorn Welding, that also applies to Canada.

When you put AWI’s 450-plus PMAs together with Acorn’s 200- plus, you wind up with just about any product you’re ever going to need. PMA means “Parts Manufacturer Approval” and it means the FAA has approved the product.

Tom Heid, the Founding Partner of AWI and its sister company AMI, said one perfect example of the merged PMAs benefiting the US customers of AWI is Acorn’s specialty in carburetor air boxes.

“Acorn has a Cessna 172 and 182 carb airbox PMA and they are working on several more models including Piper models,” Heid said. “You can buy the whole brand-new replacement air box, or you can buy the individual components if you want to repair and overhaul your own box. We (AWI) repaired air boxes through our repair station, but we had no PMAs on any of them until now.”

Another example: “Is in the turboprop market, where Acorn has a line of PMA exhaust stacks for the PT6 engine on a variety of different aircraft models.” With now more than 650 PMAs combined, there are a lot more examples.

What should be encouraging and comforting for pilots is that a wealth of knowledge in the area of exhaust and engine mounts has been merged under one roof, so when your A&P needs to work on your plane, their support will be the best in the industry. And the breadth of that knowledge takes even more explaining, because the companies listed above are further supported by Quality Aircraft Accessories (www.qaa.com),

which has offices in Tulsa, Oklahoma, and Fort Lauderdale, Florida. So, you can also buy products directly from AWI’s sister company, QAA.

Further, Acorn owns Seaplanes West, and that brings more STCs like heavy-duty engine mounts for Cessna 180, 182, and 185, and obviously a lot of products and support for float operators. Seaplanes West has an STC for several Cessna engine mounts that Heid said “gives a lot better isolation for vibration and support, especially when installing an engine with increased horsepower, or when installing an upgraded three-blade prop.” This is just another example of how the mergers create a one-stop shop.

AWI was already the world’s largest exhaust and engine mount shop; it crossed that threshold 10 years ago. AWI is based in Eagan, Minnesota, with 135 employees along with AMI, which supplies OEM parts directly to manufacturers. AWI will be celebrating its 30th anniversary in 2023.

The first layer of support that a pilot and/or their mechanic is going to get is an expert who can identify what their plane needs, which can be harder to identify than you’d think.

“Based on the make and model of airplane, there can be a variety of options for exhaust because of STCs and engine upgrades, even the OEMs have changed part numbers over the years,” Heid said. “So, when a customer calls in, we’re going to go through a series of questions with the customer to make sure they are ordering the right parts for their current installations. Our experienced customer service personnel will also give inspection tips on what to look for on a specific exhaust system, areas that tend to wear out the most, and what makes something airworthy or not airworthy.”

AWI has been featured in numerous articles in PIPERS magazine through the years, most recently in Scott Sherer’s story “New Step for Your Piper,” which ran in the July 2022 issue.

Heid is himself an A&P and pilot, and obviously knows a lot about airplane exhaust, so we asked him for his advice in that area. What are the few things that he’s had to explain to plane owners most often in those decades of experience?

“First, if you ever have a backfire, you need to have a mechanic look at that muffler as soon as possible,” he said. “A backfire is basically a disruptive explosion inside your muffler. There’s baffling or flame tubes or flame cones inside the mufflers, and that explosion can literally shatter those parts. The chunks can be big enough to where they can get lodged in the tailpipe and can’t make it out. It’ll cause you to lose power in the worst situation, which is usually on takeoff.”

“My other advice is also about the baffling, which is inside the muffler for a reason. It reduces noise and helps disperse the heat throughout the muffler more evenly. It is the first part of the muffler that typically burns out or goes bad. People complain that the baffles always burn out, but they’re there for a reason. There are some mufflers out there that never had baffles from the OEM, so they don’t have to have baffles, but if the muffler originally had baffles inside, then it needs to be in there and intact.

“And you should use it as a barometer of the health of your exhaust system. If the baffle starts to burn out or warp, it’s time to also take a look at the whole body of the muffler to make sure it’s sound, because you’ll eventually wind up with a hole or a crack in the body of the muffler, and then you will get carbon monoxide.”

That leads to the #1 piece of advice that Heid gives.

“Make sure you get some form of a CO detector in your airplane,” he said.

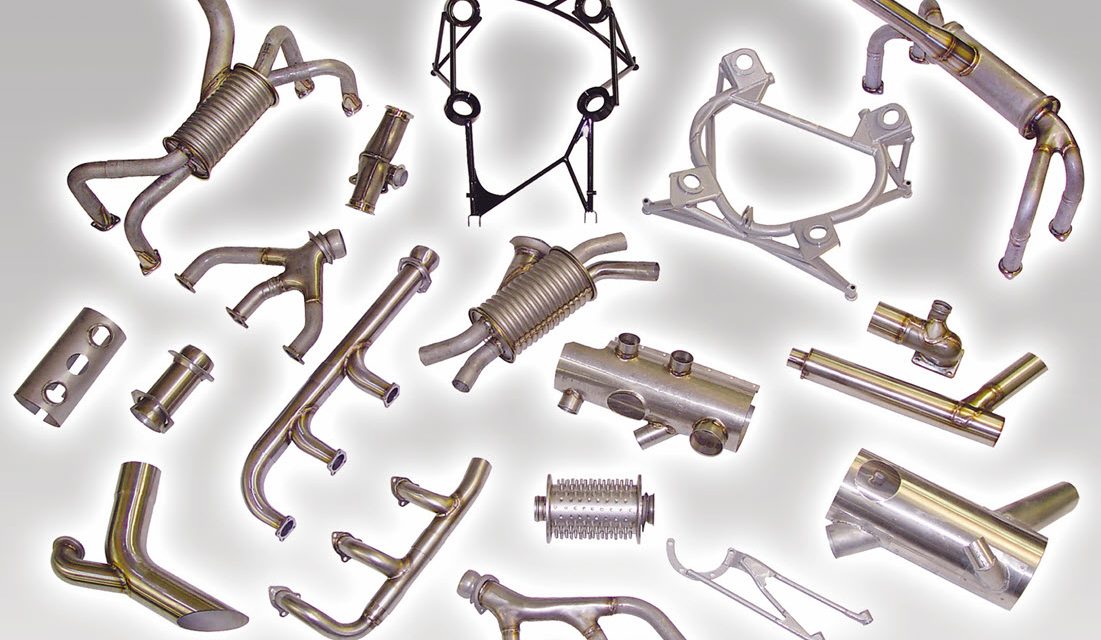

Again, from the press release, “Hartzell Aerospace Welding, established as Aerospace Welding Minneapolis, is a world leader in general aviation aircraft exhaust systems and engine mount repair. Its core competencies include certified welding, precision machining, and sheet metal fabrication.”

RESOURCES

Hartzell Aerospace Welding

hartzellaerospacewelding.com

AWI

awi-ami.com

Acorn Welding

www.acornwelding.com

AMI

www.aerospacemanufacturing.com