By Elizabeth Gibbs

AD 2011 – 10-09: Every 100 Hours or 12 Months

Many Cessna owners know about AD 2011-10-09, which requires inspection of the seat rails and seat components every 100 hours or 12 months and is applicable to most single-engine and some multi-engine Cessnas. But getting the details right is crucial. Paul New explored the topic in his May 2022 webinar.

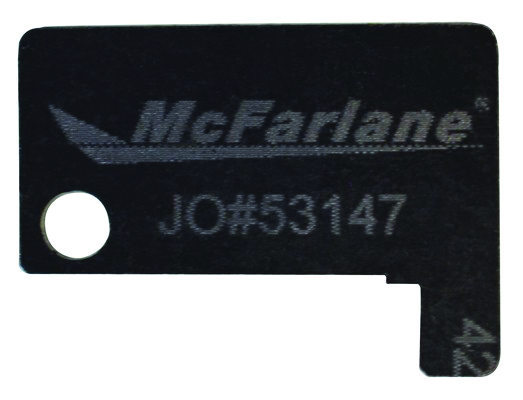

The inspection must be completed and signed off by a licensed IA. According to New, “It’s a very simple inspection to do, but it does take an hour to do if you do it correctly.” McFarlane has created a tool to help with the inspection. “This is a very cool little tool for McFarlane,” New said. The tool runs about $45 on mcfarlaneaviation.com and is handy to have, even if you’re not an IA.

“It’s a wonderful, easy Go/No-Go tool.” Owners can use calipers, but New recommends using the tool. “We find that this little tool just makes it go really quick,” he continued. “The objective here is to look into the hole in the seat rail and make sure that the hole is a nice, sharp, clean hole.”

Why is it so important? “The locking pin that keeps the seat from moving one way or another needs a good sharp edge to go against the hole in the bottom,” New explained. If it’s all rounded, that contributes to the pin sliding out. If you’ve never experienced a seat coming out of the latching pin and sliding backwards on you, I can tell you it’s a very exciting experience. Not in a good way. Just to make that clear.”

While you’re inspecting the holes in the seat rails, you’re also looking for cracks. However, “Not all cracks are bad,” New said. “You can have cracks across the holes in the top of the seat rail. That’s allowable, but you can’t have two in a row. One inch is the minimum.

“Part of this is because the seat rail is an integral part of the structure of the belly of the airplane. You can’t drill the seat rails off and fly around without the seat rails. They are a part of that structure. And that’s why if you have certain cracks, it’s not only about the seats not latching in place, but it’s about keeping the structure together of the floor of the airplane.”

And while some cracks are OK, others are definitely not. If you happen to be using your seat rails as cargo tiedowns, no cracks are allowed because of the additional stress.

New added, “This is a simple AD, but it often gets brushed over.” Don’t forget to make sure that your seat rails are checked every 100 hours or 12 months, whichever comes first!

Elizabeth Gibbs (writer) and Lyle Jansma (photographer) are private pilots and co-owners of a Cessna 172. When they’re not flying above the beautiful Pacific Northwest, they are working hard designing instrument panels for other Cessna owners. To learn more about upgrading your instrument panel, visit sixpackaero.com.