When anticipating an avionics upgrade, especially a whole-panel upgrade, we tend to put a lot of thought into the equipment, with consideration for how we plan to fly, our budget, and what equipment is best for our mission. A big part of this process is compatibility. “I like this box, this ADS-B solution, this autopilot but — do they all work together?”

My role as a consultant is to help aircraft owners lay out a plan that meets these goals, with no equipment conflicts. We tend to give little thought to the part of the installation that ties all this equipment together and makes it a system. We think about the avionics panel and the tools we use to communicate and navigate our way through the ATC system, whether it be VFR, Light IFR or True IFR. But the forgotten pieces I’m talking about are the avionics harnesses, or what the Brits like to call the “loom.”

If you have ever peeked under your panel, especially a legacy panel that has gone through numerous avionics upgrades through the years, you often find a “rat’s nest” of wires and cables, some that are no longer connected to anything. We hear stories of owners doing major panel work who, in the process, end up removing a significant amount of harness, much of which was no longer doing anything. Frankly, to me, that speaks to the quality of the avionics shops that have had their hands under there. A quality shop is not going to leave old wires behind that go to nowhere.

Harnessing up your new avionics panel has changed over the years. If you look back to the legacy avionics you saw in the ’60s and ’70s, and specifically the connectors and the wires/cables used, and compare that to today, you’ll see a lot of changes. First, all the connectors were solder-type. At some point, avionics manufacturers moved away from solder- to crimp-type connectors. I’m not sure if OSHA put pressure on the industry to get away from the use of solder, which had lead and frankly was unhealthy to breathe, or that installers just wanted to get away from the cold solder joint, the nemesis of the harness man.

Bottom line: Today almost all the connections we use in aviation harnesses are crimp-style and require an avionics shop to maintain the tools necessary to do crimp style wiring harnesses. We also see the choice of wire, or more accurately cables, most often used for antenna connections have changed. RG-58, the black stuff you can still find in legacy installations, was single-shielded and broke down over time. It is no longer used and was replaced with better quality, double-shielded cable.

I think we knew about this problem for a long time, but the advent of Wide Area Augmentation System (WAAS) GPS systems brought it all to a head. WAAS systems are much more sensitive to interference and would not perform with RG-58 or any single-shielded antenna cable, or next to another unit that transmitted over RG-58. I remember the first time we learned this lesson at Eastern Avionics, shortly after Garmin started doing WAAS upgrades to their non-WAAS GNS-430s and 530s. The first aircraft we upgraded was a regular customer’s Baron with dual 430s.

With the upgraded WAAS units back in the Baron, any attempt to transmit on either radio resulted in the loss of the GPS signal. Not only were the antenna cables an issue, but we also discovered that the Emergency Locator Transmitter (ELT) in the off position was creating a harmonic that also caused the GPS signal to drop. My understanding is today, replacing single-shielded antenna cable is required for the GNS and GTN or Avidyne navigators, or any new WAAS GPS installation.

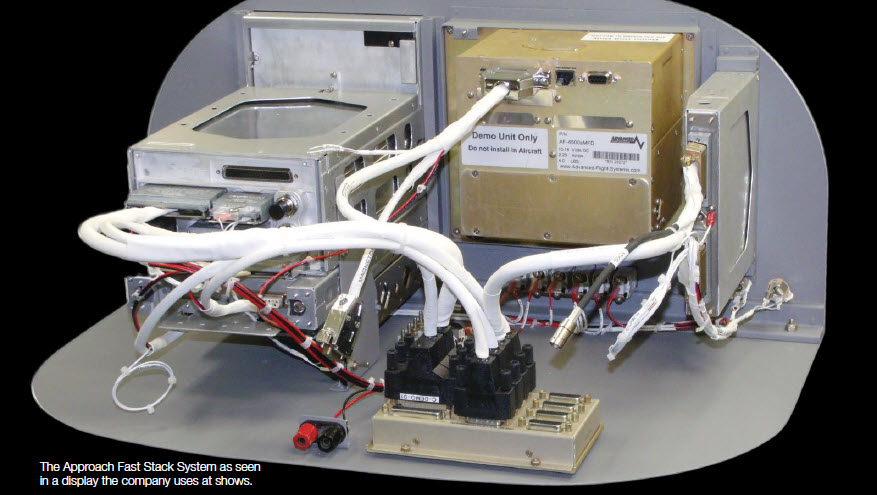

The process of upgrading an avionics panel starts with removing all the units and the mounting trays. In many cases, the mounting trays for a typical new or legacy center stack are attached to each other, making a mounting system. The trays for units being discarded are removed from the system and the new configuration with the new trays is created. Busy avionics shops like Eastern Avionics (now APG), Gulf Coast Avionics, Pacific Coast Avionics, and Sarasota Avionics likely have a full-time wiring guy whose only job is to wire up one panel after another. The new avionics are wired and those units remaining from the old stack get modified to accept their new partners. The system is tested on the bench before being installed in the aircraft, and the installer has only to mount the new system and attach power and ground and antenna connections. This is the way it has been done for years. Then, along comes the hub wiring system, an alternative to the traditional art of harnessing.

The Road to Approach Fast Stack

This is a story of two companies that came together. An entrepreneur from Provo, Utah, essentially invented what is now called the “hub” system. We will talk about that concept in some detail. That company was known as Approach Systems and their primary market was experimental builders.

Meanwhile, Tom Hass, with lots of avionics experience, opened his new avionics shop, Park Rapids Avionics, in 2001 in Minnesota. Tim Hass joined the company in 2003. In 2006, a Piper Malibu owner came to Park Rapids Avionics with an avionics upgrade in mind, and that pilot was aware of Approach Systems and liked it and wanted it for his Malibu upgrade. He introduced the Hass’s to the owner of Approach, who just happened to be thinking beyond Approach, and Park Rapids decided to purchase the company. Approach Fast Stack was born. It was decided that Tim would grab the reins and run the new division.

The Approach Fast Stack System

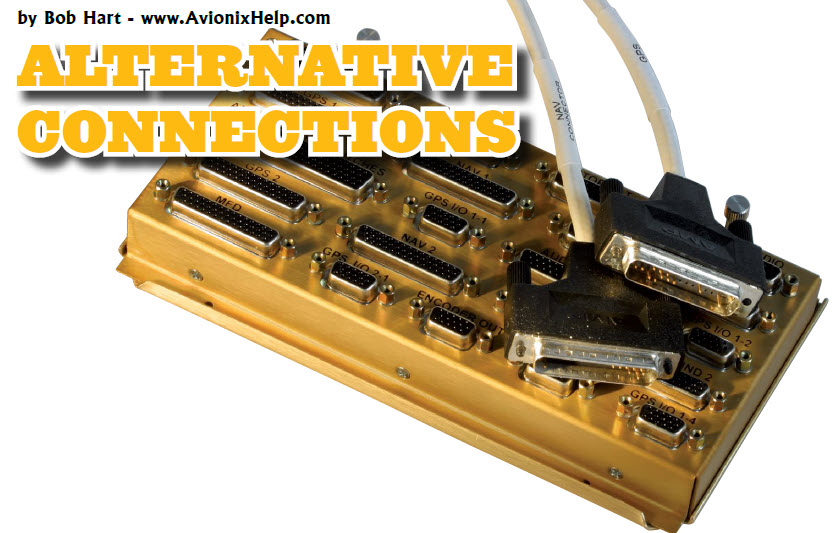

The heart of the Fast Stack System is the hub. The principle of the system is that all individual harnesses (provided by Approach Fast Stack) for each piece of avionics plugs into the hub, which is mounted to the firewall or some other location under the panel. Approach offers two different hub options:

PRO HUB (IFR CENTRIC)

The Approach Fast Stack Pro Hub is ideally suited for IFR-configured instrument panels and can be retrofitted to any older or newer aircraft, certified, or home-built. The Pro Wiring System is compatible with most nav/GPS/comm, modern audio panels, intercoms, moving map displays, VHF omni-directional range (VOR) indicators, Horizontal Situation Indicators (HSIs), Radio Magnetic Indicators (RMIs), Automatic Direction Finders (ADFs), annunciators, mode control, and just about any “send and receive” RS-232 formatted electronic device. The Pro Wiring System is designed for a full Garmin, Apollo, or Bendix/King stack and other legacy avionics and includes an autopilot interface.

PRO-X HUB (IFR EFIS CENTRIC)

The rest of this article can be seen only by paid members who are logged in.Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

JOIN HERE

Still have questions? Contact us here.