By Carl Ziegler, A&P/IA

All photos courtesy of NTSB report

Back in the later years of the 1970s, specifically, around 1977, I was just coming out of my disco phase and was learning the ropes as a fledgling aircraft mechanic. I was taking a break from college and working full time at an FBO on the far South side of Chicago, at the old Chicago Hammond airport. Those were very busy years for general aviation, and our maintenance operation was no exception. We took care of the FBO’s flight training aircraft as well as a Part 135 operation comprised of a very early model Navajo and a couple of Beechcraft Barons. “Jumpin’ Joe” was an interesting character, as the owner of the FBO. He also used the Navajo for his own personal use and, on this occasion, he had taken it to Steamboat Springs, Colorado, for a round of skiing. Normally this wouldn’t be an issue for any aircraft, and Joe was certainly an accomplished pilot. One thing he neglected to calculate was that he was departing from summertime conditions and flying into a winter wonderland. The problem was that both engines of the Navajo still had straight-weight Aeroshell 100 in the sumps for our operations in the Midwest. Keep in mind that multi-viscocity aviation oil was not introduced until 1979. You had to pay attention and know the limitations of aviation oil based on expected temperatures en route and at your final destination. We have it so easy today!

After Joe and his cohorts enjoyed the winter wonderland, it was time to depart back to the Chicago area. Joe finally realized that in the close-to-zero-degree Fahrenheit temperatures, it might be hard, if not impossible, to start the engines with 100-weight oil still residing comfortably in the bowels of a pair of TSIO-540s.

At this time, Steamboat Springs was pretty much a one-horse airport — or maybe even a one-fuel-pump airport — with no services. After multiple attempts, Joe somehow managed to get the engines running and decided to perform a no-passenger warmup flight around the pattern to make sure there would be no issues. Well, after he somehow managed starts at those temperatures with no preheat, he blasted off around the pattern leaving a smoking trail of white exhaust. The engines were now in the process of chewing themselves up for a two-minute flight due to congealed oil in the lines, the turbochargers, controllers, and the oil coolers. Pucker in the pattern!

You can guess the outcome. We now had two boat-anchor engines that were 1,300 miles away and 6,800 feet in elevation at an airport with no hangars and no service. Oh, did I mention it was still winter and cold?

I was not the one chosen to go with Jim to change two engines under a couple of tarps and a kerosene heater for warmth. Joe had managed to get G&N Aircraft to produce two complete engines, which Jim and our helper loaded into the back of a U-Haul with the necessary equipment. I think it took them over two weeks to change both engines out in the cold, with no support. I always felt a bit cheated for not going with Jim on that deal. But in retrospect, after spending several decades outside in Minneapolis working for Northwest Airlines as a line mechanic, I realized I didn’t really miss out on anything.

A More Recent Accident

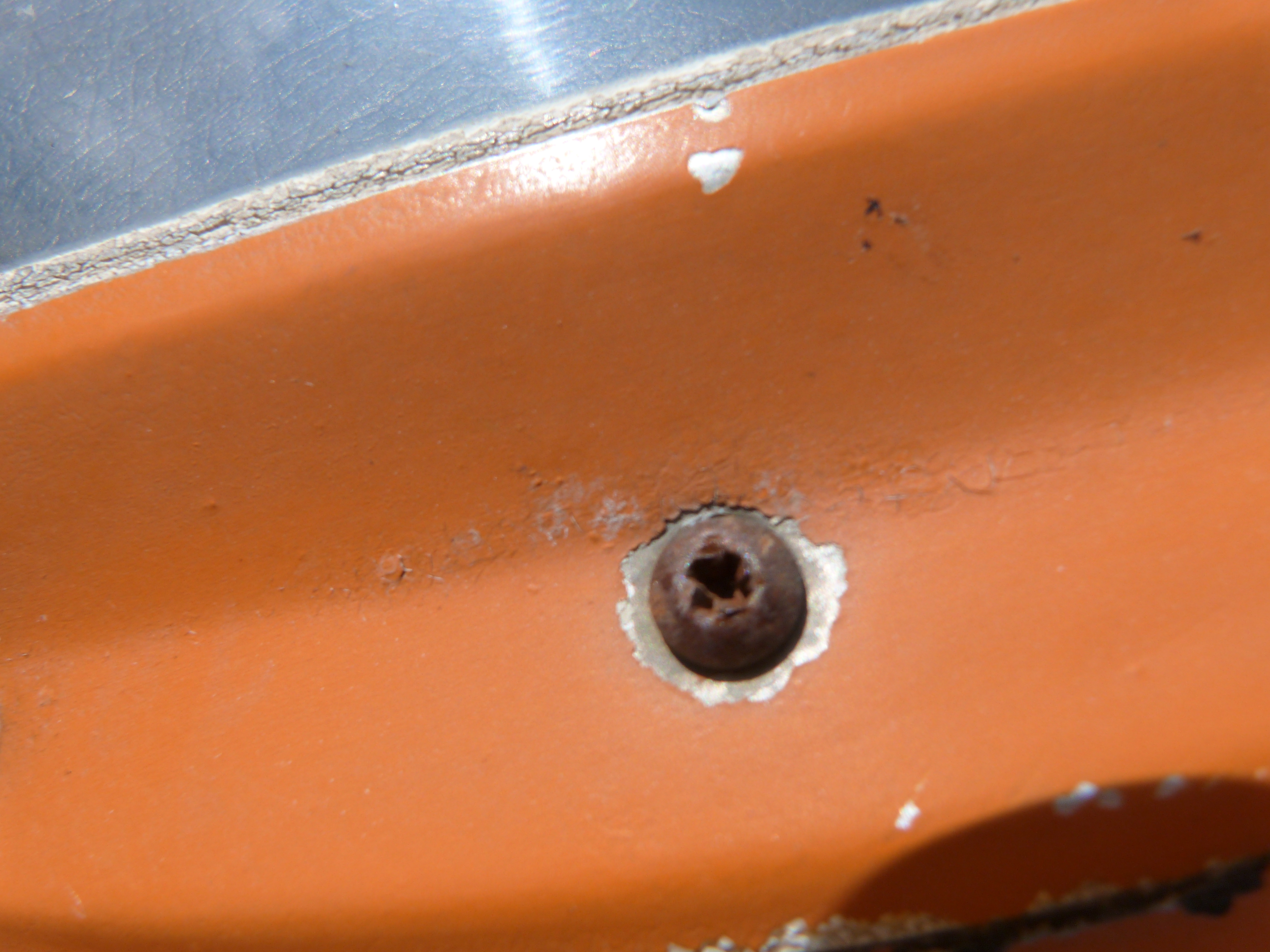

Take a look at the photograph above. Here’s a 172 that’s upside down and met its fate on a boulevard of dreams lined with trees. This very recent accident is what spurred my memory of the Navajo stuck in Colorado. As I read the accident report, which luckily did not involve any fatalities, I had to laugh at the fact that the issues that caused the Navajo incident so long ago are still valid problems that manifest themselves even today.

Accident Narrative

Location: Auburn Hills, Michigan Accident Number: CEN23LA067

Date & Time: December 21, 2022, 14:47 Local

Registration: N8768U

Aircraft: Cessna 172F Aircraft

Damage: Substantial

Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

JOIN HERE

Still have questions? Contact us here.

Carl has close to 50 years of continuous experience working as an aircraft technician and 38 years as an IA. In addition to GA, he has acquired over 38 years of airline experience with Northwest and most recently with Delta, finishing his last 13 years of airline service as an aircraft inspector. He currently flies a 1976 Cessna 172N.