By Scott Sellers

182RG Owner & COO Editorial Board Member

This is the next in our series about our 182RG, and we begin with a recap of items from the prior article, which covered getting to know our new-to-us Cessna faster. Learn the first four things you should do to learn your new-to-you Cessna in this article.

Probably the most useful connection we’ve shared from this series is finding all mandatory Airworthiness Directives (ADs), recommended Special Airworthiness Information Bulletins (SAIBs), and optional, informational, and non-applicable Service Information documents that apply to your airplane. Visit https://ww2.txtav.com/TechnicalPublications/SI and also read item 2 from “Get the Published Docs” (Page 29 in the November 2021 issue) and follow the step-by-step procedure.

That website will create a complete list of documents for your serial number airplane, and you’ll want to save the site in your favorites, since you’ll be going back there to pull up each individual document as you need them. Once you’ve created your login, the site then sends automated Service Information Notification documents published in the future. For instance, we received the SEB-28-04R1 Unleaded Fuel Placard installation notice October 25, 2021, which was published October 19, via this automated delivery. Shortly thereafter, Textron made their public announcement about unleaded fuels being an option for Cessnas with Lycoming engines.

After you accomplish the four things in that first article, and those publication instructions above, here are the three things you should do to your Cessna today.

Prop Governor Overhaul

Our last article suggested overhauling all engine accessories immediately upon acquiring your Cessna as an option for best reliability. However, I did not follow my own advice. We chose not to overhaul our prop governor during the prop overhaul. That was a mistake.

I have found that on hot days, prop rpms sometimes surge a little on takeoff. This is a prop governor issue, I hope. The governor will come off this winter and be sent out for overhaul after 18 years and 1,450 hours of service. No money was saved by delaying this overhaul, and unpleasant looks from my wife asking, “what’s going on here?” come with no good answers when the propeller surges slightly on takeoff.

Nose Wheel Torque Links

We also pointed out in our last article the importance of the nose wheel torque link condition, since safe ground handling is dependent on it. The ideal condition of your nose gear torque link is that it does not move at all when you grab it and try to move it side-to-side. When there is movement, or you can hear/feel it moving, that means it should be addressed.

Sometimes simply pumping grease into grease fittings stops the movement. After rebushing our 182RG torque links, all new hardware was installed, including new attachment bolts, washers, nuts, and shims to tighten the gap between torque link and nose strut housing.

Grab the torque link now and try to move it, and it’s as solid as a rock — no movement. This is how it should be. McFarlane sells torque link rebuild kits (or the hardware items individually) to rebuild your Cessna nose gear torque link. You can also get the McFarlane kit on Aircraft Spruce’s website.

Dynamic Propeller Balancing

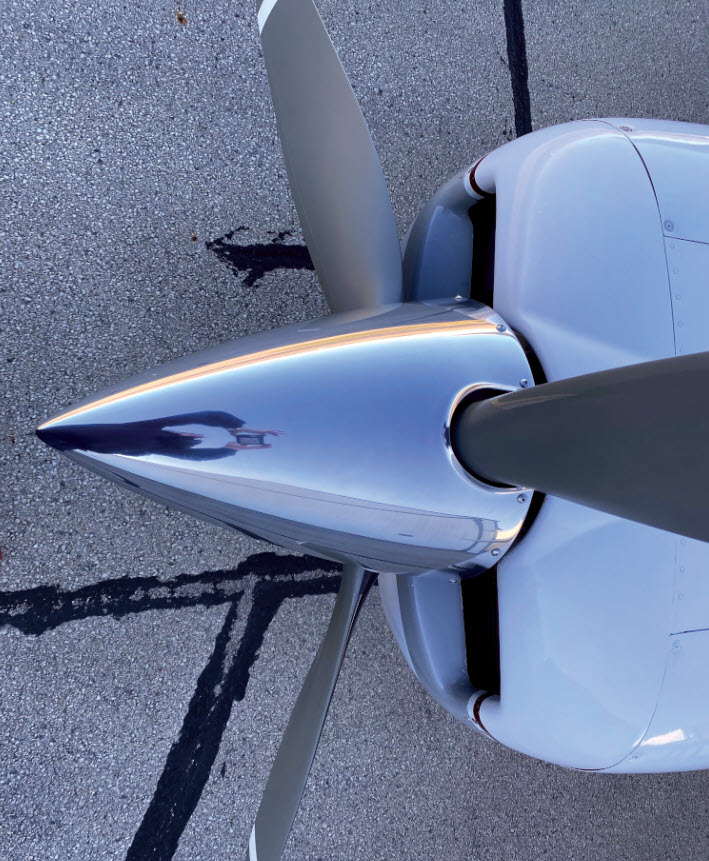

Since our 182RG’s prop was installed in 2003 as a factory-new Hartzell HC-C3Y-1RF/F8468A-6R and had not been removed since then, we chose to have it overhauled shortly after buying the airplane. Why do that, since it’s rather expensive? For one thing, our A&P/IA mechanic balked at signing off for annual inspection on a prop he had not seen before, was in service for 17 years continuously, and has more than 1,400 flight hours based in the Arizona desert.

Also, while the blades looked to be in good shape, I was concerned about the condition of the hub, since desert sand can be found all over the airplane. Sand in the hub could be a problem. After keeping fingers crossed for the two-month wait, the prop shop reported the hub was in good shape and the blades had enough “meat” (their term for metal thickness) remaining for one more overhaul.

With new propellers, you would expect enough available metal thickness for three or even four overhauls. But this prop was now zero-timed, and we knew it would be safe to operate for years, so this is a good outcome regardless.

The propeller overhaul shop statically balanced the propeller before and after painting, with outstanding results. The finished product looks like a piece of artwork. We chose to not include the Hartzell stickers on the blades, since they erode and look worn fairly soon after return to service.

All propellers come from the factory or the prop shop statically balanced to ensure all blade weights are identical. What’s different with dynamic balancing is that it measures vibration of the engine/propeller as a system, while in operation. It is invaluable information that can be identified and resolved in a few hours and remains balanced for hundreds of flight hours and many years. Our 182RG was flown 15 years and 1,400-plus flight hours since the last dynamic balance. See your prop log entries to confirm.

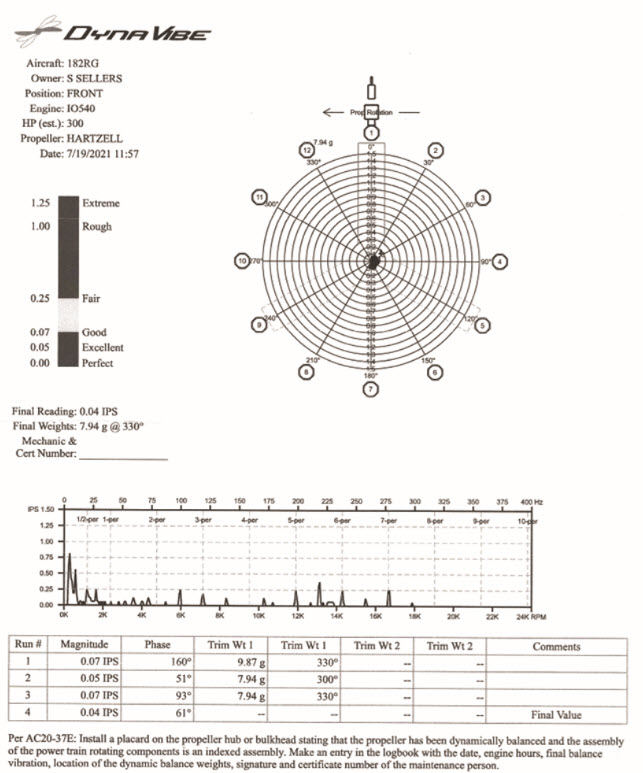

Dynamic balancing is performed with specialized equipment that precisely measures vibration and pinpoints the exact location of imbalance.

Dave Pasquale of Pasquale Aviation balanced our prop and uses the DynaVibe GX3 system by RPX Technologies. It is made up of an analyzer with accelerometers that attach to the engine case to measure vibrational movement. The GX3 system is capable of measuring rpm during testing and exact prop position so the amount of movement can be correlated to the prop’s position to create a solution to the imbalance. In the case of our 182RG, there was no perceptible vibration difference in the cabin after the dynamic balance, but there remain substantial benefits from prop balancing.

Why Balance Your Cessna propeller?

The propeller logbook showed it was new when installed in 2003 and was dynamically balanced in 2007. So, after the May 2021 overhaul and about 15 flight hours, we decided it was time to dynamically balance it again.

Why do that if it was statically balanced and there was no perceptible vibration, panel instruments were not vibrating, and all seemed well? To answer the question with a question, how often have you heard someone suggest their new/overhauled prop is running smoothly so they don’t need to have it balanced? Wrong!

If your engine’s rubber shock mounts are functioning well (ours are less than a year old and were replaced at the prebuy inspection), they behave like vibration isolators. Thus, you cannot sense vibration during flight well enough to know if the spinning mass of your engine and its prop are well-balanced.

Our overhauled prop felt super-smooth in flight, but the DynaVibe balancing system showed it to be at 0.07 inches per second (IPS) movement and merely Good. After four runs, Pasquale Aviation was able to achieve a 0.04 IPS Excellent result, as seen in the chart. Keep in mind if you remove and reinstall your propeller for repairs, or if a substantial change to the engine is made (i.e., overhauled accessories or cylinders), then it is a good idea to recheck the dynamic balance.

Maybe the best reason for dynamic prop balancing is engine longevity. I have not seen any data for this, but running our engines to TBO and beyond can only be helped by dynamic balancing. Lycoming confirmed they have no data on this topic, but that engine lifecycle and longevity would be improved by dynamically balancing the propeller/engine system.

Lycoming Technical Service also referred to Service Bulletin 245D, which mentions detuning of the counterweight system can occur when the engine operates outside of its normal range and by abrupt throttle change. Lycoming recommends a minimum three-second advancement of the throttle to full power so that counterweight bushings are protected, damage to which can cause harmonic imbalance.

Recently my brother had to overhaul his engine due to worn out crankshaft counterweight bushings whose wear is impacted by the dynamic balance of the spinning mass of the prop and engine. And his engine ran very smoothly in flight.

Dynamically balancing your propeller completes the setup of your newly overhauled propeller and/or engine and brings long-term value and lowered cost to your airplane’s operating budget. The service usually ranges between two and four “solutions” (engine runs, generating a vibration data point) for the mechanic to address the imbalance and reduce vibration.

Typical cost to dynamically balance your propeller is $300-$500, so dividing that out over a 10-year period indicates a $30-$50 annual cost between prop or engine overhauls. Sounds like a deal to me in the world of aviation budget items.

More Cessna Research

Why you shouldn’t ignore vibration: Propeller balancing advice by DynaVibe.