FAA Considering Adding 177, Plus More 210 Models, to Carry Through Spar AD

This article summarizes also previous coverage and includes links to all previous documents including Service Letters.

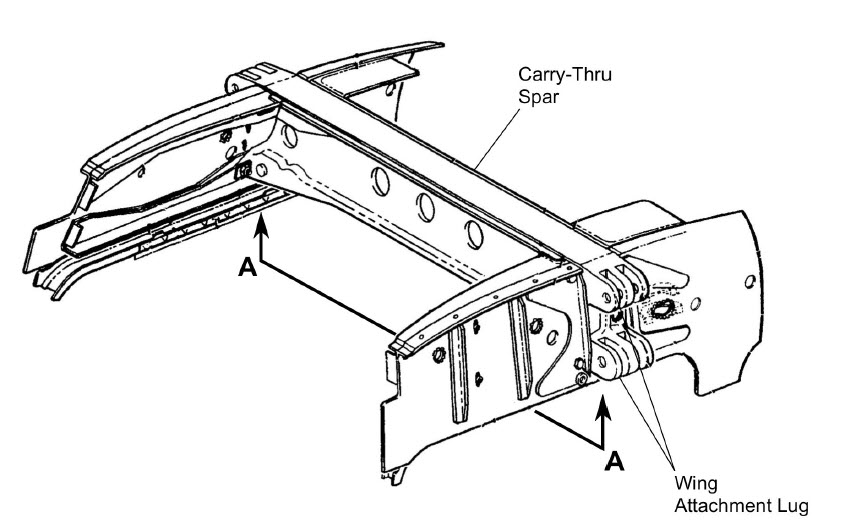

The FAA is considering adding 177 models to the carry through spar corrosion AD previously targeting only 210 planes, and it issued an NPRM in May, 2021, with public commenting open until June 25. It is also considering adding more 210 models to the AD.

Summary of events leading to a possible 177 spar AD and expansion of the 210 AD:

- The in-flight breakup of a 210M in Australia two years ago prompted an ACS (airworthiness concern sheet) in June 2019 for many models of 210.

- Further investigation led to AD 2020-03-16, again for 210s.

- Because 177s share a similar carry through design, they were investigated, leading to this NPRM and this commenting period.

- Other 210 models that weren’t in the original AD are also being considered in this NPRM.

Most NPRMs lead to full-fledged ADs. Here’s the list of applicable planes that are either in an AD already or are mentioned in this NPRM: Models 210N, 210R, P210N, P210R, T210N, T210R, 177, 177A, 177B, 177RG, and F177RG airplanes, all serial numbers, certificated in any category.

The NRPM has much more detail and we encourage you to read that (link below) to ensure you know if your plane is covered.

“It doesn’t surprise me that an expansion of the AD is being proposed. There have been aircraft inspected and found to have previously undetected issues discovered,” said Erich Rempert, Cessna Owner Organization A&P/IA consultant. “That said, the final version of this (or any) AD needs to have focus and vision with the goal of keeping these airplanes safely in service, not grounding them.

“The aircraft maintenance industry is currently at or beyond capacity in many areas of the country, and a wave of eddy current inspections all to be completed by a certain calendar date is a formula for a ‘rush job,’ and that’s exactly contrary to what should be desired.

“I don’t feel the FAA’s labor estimate takes into consideration the amount of work (and potential unforeseen tasks) necessary to get an aircraft into a condition where the inspection can be performed. I have heard reports that the preparatory part of the project was the lion’s share of the work.”

Rempert also noted that some shops are better equipped to handle this inspection and repair than others, again adding to the necessity of the FAA being flexible with the timeline of this upcoming rule.

“Flexibility needs to be built into this rulemaking to allow every owner to obtain high-value attention vs. a strict ‘paperweight/calendar date’ approach.”

COO aviation director Scott Sherer urged members to take the situation seriously, and to address it soon.

“I urge our members to take these ADs seriously,” Sherer said. “Metal fatigue and corrosion get more expensive if we procrastinate. Make an appointment with your A&P soon to discuss these issues.”

More information:

- May 2021

- Read the NPRM here.

- To make a comment, use the link above, then look for “SUBMIT A FORMAL COMMENT” in green top-right.

____ - August 2020

- Read an updated/corrected Service Letter for the 177 (SEL-57-09R1) here.

- Read an updated/corrected Service Letter for the 210 (SEL-57-08R2) here.

____ - February 2020

- Read the original 210 Carry Through Spar AD here.

____ - November 2019

- Read the second Mandatory Service Letter (SEL-57-08) involving the 210 here.

____ - June 2019

- Read the original Mandatory Service Letter (SEL-57-06) involving the 210 here.

- Read the original Airworthiness Concern Sheet involving the 210 here.

____ - June 2019

- Read the original Mandatory Service Letter (SEL-57-07) involving the 177 here.