Under the Cowling

6 Simple Strategies to get your Plane in Ship-shape for Spring

For most folks, the warmer temperatures of spring bring a longing to get outdoors and enjoy activities that have been neglected during the cold winter months. Most pilots don’t fly as often in the winter, so many airplanes sit unused for extended periods of time. The first spring pre-flight can be a challenge, particularly for planes that are stored outside. Make your initial spring flight a success with the following tips designed to wake your plane from its winter slumber and get it set to soar:

Tip #1: Melt away Unwanted Weight

If the temperature is below freezing when doing a preflight, it’s a good idea to make sure there is no ice in the control surfaces. Snow that has melted and re-frozen or water that has frozen overnight can collect inside parts of the tail or ailerons and cause a control surface to be badly out of balance. It is best to pull the plane into a heated hangar (if available) to let it thaw out.

Tip #2: Take Charge of Your Battery

Unused batteries are typically low on charge if they have been sitting in the cold for a while. Pulling them out and placing them on a slow “trickle” charge overnight will help bring them back to life. If the battery is not a sealed unit, the caps should be removed and the electrolyte level checked. (Note: because the electrolyte level expands some as it is charged, the battery should be serviced when it is fully charged). Should the battery need attention, those serviced with electrolyte, NOT water, perform better. Over time, simply adding water will dilute the battery acid too much—this, in turn, will shorten battery life. Of course, there are precautions to be taken when adding acid to water, but unless the electrolyte in the battery has been extremely diluted, there should not be a reaction when adding more electrolytes. It’s also a good idea to flush out and clean the battery box. Before using large amounts of water in the box, be sure the drain is clog-free and does not leak. A little baking soda will help neutralize any acid residue in the box.

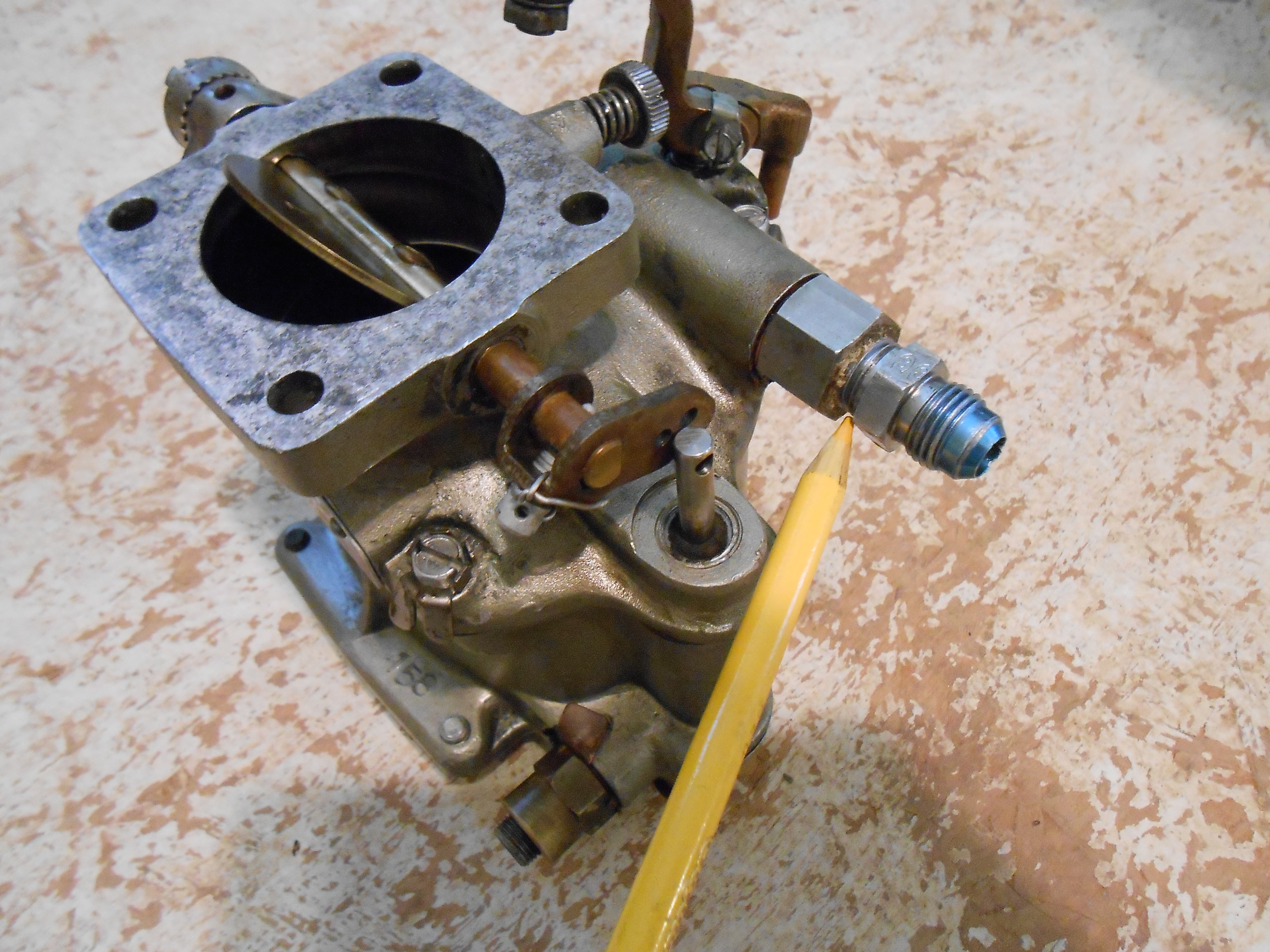

Tip #3: Get your Motor Running

An engine that hasn’t been operated in a while can be a challenge to start. Carbureted models that have been stored with automotive fuel in them can sometimes have varnish in the carburetor. In extreme cases, the carburetor may even have to be overhauled! Sometimes, primer nozzles can clog and will need to be cleaned. To do so, remove the nozzles and soak them in carburetor cleaner or battery acid. Then, rinse with gas or contact cleaner and blow them dry. Fuel injected models are the easiest to start in cold weather, though the injectors may need an occasional cleaning. Prior to starting any model, remove the spark plugs and squirt a little oil directly into the cylinders, while pulling the propeller through by hand. This really helps to pre-oil the engine and limber everything up. Before re-installing the plugs, let any excess oil drip out of the lower spark plug hole so the oil doesn’t foul out the bottom plugs.

Tip #4: Pump-up Tire & Strut Performance

Tires and struts are usually low after the cold months. Servicing them with nitrogen rather than air helps the pressures to remain steady for longer periods of time. Struts that continuously go flat can sometimes be serviced with a mixture of hydraulic fluid and Granville sealant. Typically, when the Granville sealant is used the strut will still deflate and need to be aired up a couple more times. However, once the chemical has made thorough contact with the seals, the strut generally stays inflated. The sealant does not swell the O-rings; it simply makes hardened, brittle O-rings more pliable so that they can, again, form an air-tight seal. Once struts are properly inflated, wiping them down with hydraulic fluid helps to clean off impurities and prevent corrosion.

Tip #5: Limber Up with the Right Lubricants

If conditions permit, washing an airplane is a good way to inspect the entire exterior surface— and improve its looks too! Once clean, a thorough inspection can begin. A bright light should be used to check in openings for any bird nest or bee hive residue left over from the previous season. All antennas should be cleaned and attachments checked. All the hinges and pivot points for all the flight controls should be lubed. LPS2 is a good lubricant for hinges, while LPS3 is a good product to spray onto the surface of areas that are starting to corrode. However, because its waxy coating is so thick, LPS3 does not penetrate between surfaces very well. Corrosion X or ACF 50 may work better for such applications as they penetrate deeper to help slow corrosion. Cessna flap jack screws and Piper trim tab screws should be lubed with Lubriplate.

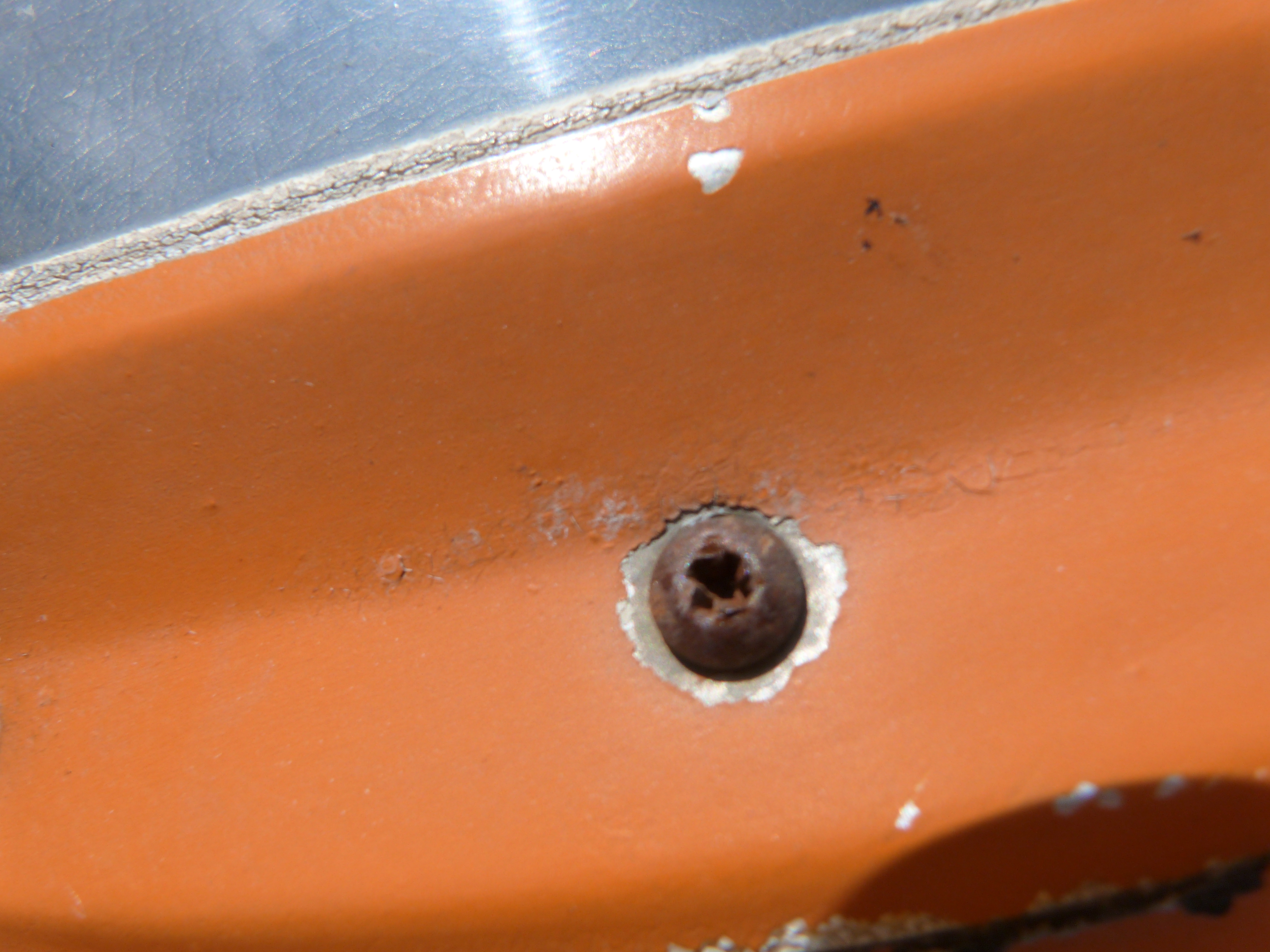

Tip #6: Freshen your Fuel

Fuel tanks that haven’t been drained in a while should be thoroughly sumped and checked for water. If the seals aren’t too terribly deteriorated, clogged fuel tank drains can be removed and cleaned. If the seals are bad, the sump drains have to be replaced because the seals are no longer sold individually. Most sump drain valves have a tapered pipe thread. The best thread sealant for anything in contact with fuel is a product called Thread Lube. It is sticky, seals well against fuel, and the parts are easy to remove the next time there is a need for disassembly.

The first pre-flight after a long period of inactivity should be a thorough one—not only to discover any hazards, but to prevent extra wear and tear on the plane once it flies again.