By Jeff Ferguson, Aviation Fabricators

Most Cessna 100-200 series owners are familiar with the term “rocking chair.” It’s not an invitation to sit back and relax. Rather, it is a term that should gain your immediate attention. When a Cessna seat frame is so loose that it literally rocks back and forth on the seat rails, it becomes a safety issue. The seat can potentially depart from the seat rail. This scenario is addressed in FAA Airworthiness Directive AD2011-10-09.

What Causes Your Cessna Seat to Become a “Rocking Chair?”

Technicians at Aviation Fabricators (AvFab) see three primary causes when they service and repair seats.

- Elongated roll-pin holes

- Bent, flared, or worn roller housings

- Broken or bent seat tabs (also referred to as “legs”)

Next Steps

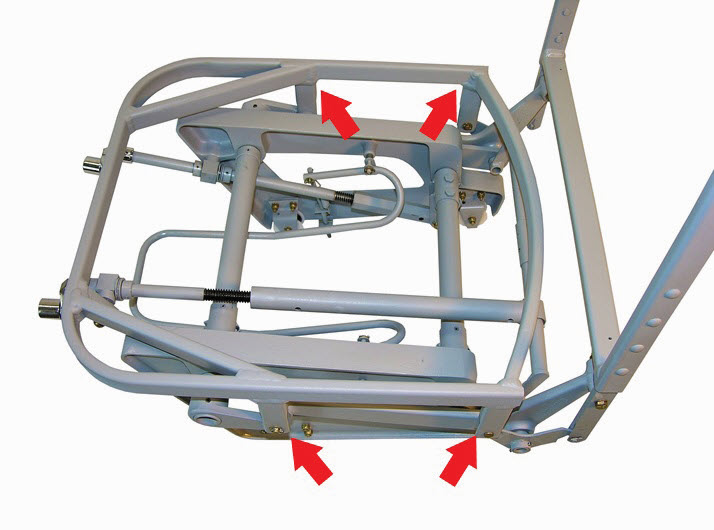

AD 2011-10-09 spells out the specific steps of visual inspection and the sequence of actions required to measure tolerances to the:

- Seat rollers, washers, axle bolts, or bushings

- Seat roller housings and the tangs

- Lock pin springs

In addition to the three primary issues stated above, a thorough inspection of the bell cranks, pedestals, and seat frame assemblies for metal fatigue (such as fractures, cracks, or distortion) must be performed on a recurring basis.

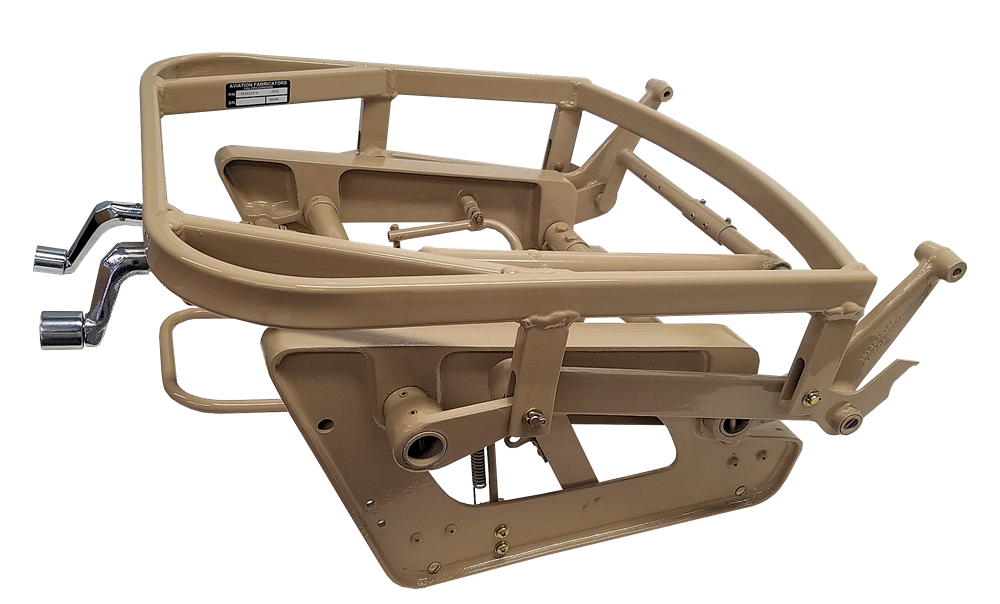

Cessna used both aluminum and 4130 chromoly steel tubing in these seats. Each repair requires welding skills beyond the average aircraft owner’s abilities when cracks or breakages are found. One of many things AvFab pays special attention to is the seat tabs. They replace the OEM leg, which is hollow, with a solid, milled leg, which is far more robust and less prone to cracking and bending. On average, each seat requires over 20 labor hours to refurbish.

Aviation Fabricators (AvFab) is an FAA/Certified Repair Station in Clinton, Missouri. They specialize in repair and refurbishment of aircraft interior seats. Repair technicians can save pilots substantial time and money when compared to ordering a replacement base or seat assembly from the factory. We take great care to preserve the chair foam and covering so they can be reinstalled after the repairs have been completed, if necessary. Refurbishment complies with Service Bulletin SEB 11-4 and/or Airworthiness Directive AD2011-10- 09. All repairs are certified with an 8130-3 Return to Service Document. AvFab will be at EAA AirVenture in Oshkosh July 21-27, 2025, in booth #1139. We are a co-sponsor for the COO “Meal with Members” on July 21, 2025, during EAA AirVenture.

Learn more about AvFab at www.avfab.com