By Scott “Sky” Smith

This article started out with me thinking about what an aircraft owner can do to get ready for the coming cold weather. Bears hibernate, boats and RVs are winterized, but airplanes are often forgotten.

A really simple way to take care of your aircraft is to avoid parking it for any length of time. By that I mean you should be flying every week. But in reality, most of us don’t have the time for that so we have to make plans for taking care of our aircraft in other ways. If you are not going to fly it every week, there are a few things that you should consider. Now that I think about it, you could really use this list every time you preflight your aircraft, but for now let’s call it a fall checkup.

Again, the key about getting ready for the fall and winter months is to not stop exercising your aircraft. Don’t stop flying — period! Winter is hardest on the northern pilots, but no use is bad anytime, anywhere. The worst thing you can do is not use your aircraft! If you can’t fly the aircraft at least 30 minutes to an hour a month, you should at least ground run it. But don’t just run it for a couple of minutes and put it away. You need to run it long enough to bring the oil temperature and cylinder head temperature up to the green arcs. This will keep the upper part of the engine lubricated and free of moisture and corrosion. Another benefit of running the aircraft is it will allow the gyros to spin up and keep the bearings from pitting.

Aside from running the aircraft regularly, I have compiled a few additional things that the average owner could do. Talk to your mechanic for more details and further recommendations.

Oil

First let’s start with the “life blood” of the engine: oil. It’s important to change your oil at least every six months or every 25 to 50 hours. Oils can develop acids and other contaminants that are hard on the engine. If you haven’t changed the oil, this might be a good time. In my opinion, oil breaks down whether it is doing its job of lubricating and cooling the engine or if its just resting in the oil pan. So, change the oil whether you fly or not; fresh oil is cheap compared to the cost of an engine overhaul.

Exhaust Systems

Cold weather finds us using the heaters more. Many aircraft heaters are tied into the exhaust system in some manner. So, checking the heating and exhaust system should be high on the to-do list. Mechanics can do pressure testing of exhaust systems to look for leaks. If yours hasn’t been tested, test it. Carbon monoxide is a dangerous thing. It’s surprising how many people have been sickened or killed in aviation by exhaust leaks. If you have a separate heater make sure it is serviced.

Fuel Systems

Fuel systems need special attention. Whenever you park the aircraft, make sure that you keep the fuel tanks full. If there is very little room for air, there will be less moisture and less chance of water in the fuel system. If your aircraft has bladder tanks, keeping them full will help keep the bladder material from drying out.

As pilots, we are trained to check the sumps before we fly to look for water. But what happens if we find water in the tanks? Remember, I’m not a mechanic so I’m just relaying information here; it is always best to talk to your mechanic if you have a lot of water in the tanks. Through the years I have been told to drain out all the water that you can with the sump drains, then add about 10 ounces of isopropyl alcohol for every 20 gallons of fuel. Don’t get carried away with the alcohol — too much can deteriorate the rubber parts in the fuel system. You are probably asking, why use isopropyl alcohol? I have been told that methanol only mixes with the water and keeps it from freezing, while isopropyl alcohol molecules combine with the water molecules making it light enough to move through and out of the fuel system. There is probably more to it than that simple explanation, but it’s still a cool science tip.

This article originally appeared in the October issue of Cessna Owner magazine.

Whether you intend to let your aircraft sit during the winter or you just don’t have time to fly as much as you should to keep it in good flying condition, you still might get water in the fuel. Somewhere I read that almost 90% of the water you find in the fuel system is from condensation. This condensation can be from your own aircraft or from your fuel supplier. Basically, that means there is always a chance of water in the fuel but flying less in the fall and winter might mean a higher risk.

Brakes

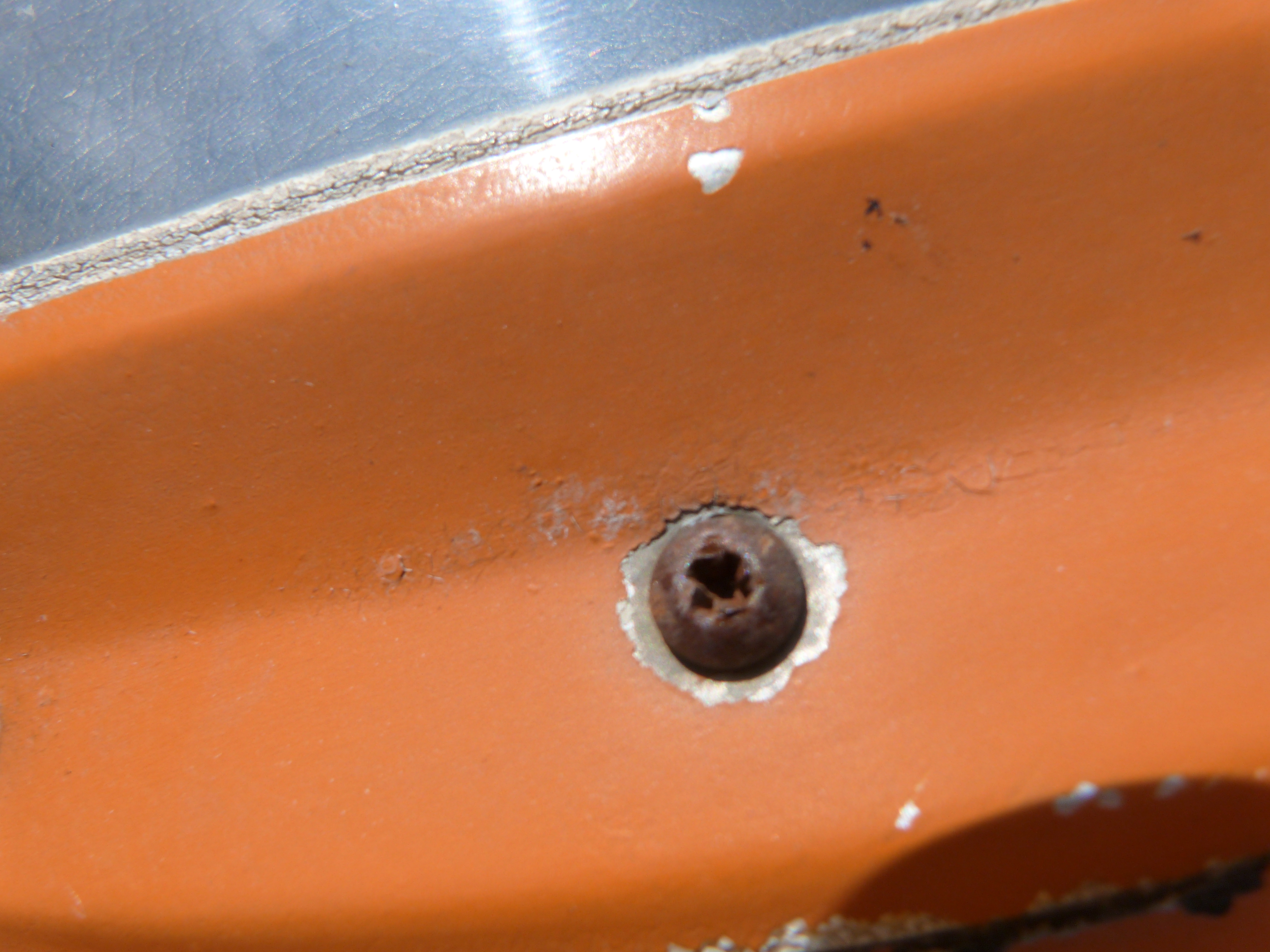

Most pilots do a preflight and look at the control services, check the fuel, oil and cowl openings, etc. But how many of you check the brake pads and brake rotors? The lower parts of the aircraft are often neglected. We’re talking about the wheels, tires, brakes, and bearings. If the brakes work, the wheels turn, and there is air in the tires you don’t need much more, right?

Well, many owners forget that the brakes and wheel bearings draw a tremendous amount of moisture. If you leave an aircraft parked, the lowest, most humid location is around the wheels. Brake discs rust, brake pads get glazed over, and wheel bearings stick. Often you won’t notice the rust in the wheel bearings until they freeze up suddenly causing a mishap on landing. Cleaning and repacking bearings is essential on a regular basis. The grease or lubrication is the only thing that is going to keep the moisture out of the bearings.

If you have a tailwheel aircraft it is especially important to check these areas and the tail wheel components, including the attachment points and the rudder posts, before flying. We have had insurance claims turned in where the tail wheel attachment rusted away and the wheel broke off. Not a good thing.

Read Jim Cavanagh’s article on changing brake pads in the June issue of Cessna Owner magazine.

Preheaters

Do you use a preheater? Preheaters can make the difference between flying or not. Starting an engine in really cold weather without a preheater is very hard on the engine. The oil is thick and doesn’t flow, which means it won’t do its job lubricating the engine. A preheater is a must. So, if you have an external preheater, make sure its serviced and ready to fire up safely without leaks when the weather turns cold.

If you have an engine heater, make sure it’s correctly installed, works properly, and you have the appropriate extension cords to keep the engine heated. And don’t forget, when you go flying in cold weather, you’ll need a long extension cord to take with you. If you park the plane for any period of time without a cord, you might not be able to start it up to get home.

Speaking of cold weather, I remember flying my brother’s 1946 Stinson with a blanket stuffed in the door cracks and another blanket over our legs. It really needed some new door seals. Take the time to check and replace the seals on doors, vents, etc. Door seals are cheap compared to freezing and they work much better than a roll of duct tape. Not that I’ve taped up any gaps in an airplane before.

If you have a retractable gear aircraft, fall is a good time to check all the doors and linkages. You want the gear to work right all the time, but it seems more likely that you’ll run into rain, mud, snow, slush, etc. during the fall and winter months. The gear doors need to be in excellent working order so little things like “freezing slush,” don’t lock up the gear retracting systems.

Batteries

Another thing you need to do is keep your batteries charged or have them attached to a battery tender. When a battery goes low it can freeze and break. If temperatures don’t get below freezing in your area, a dead battery it is still a problem. I can tell you from personal experience, hand propping an airplane with a dead battery is not something you want to do regularly or even once.

If you hangar your aircraft, check out your hangar doors and get prepared for the snow and ice dams that can happen. I have numerous stories and claims from aircraft that were stuck getting out of the hangar, or people fell, or hangar doors stuck — the list goes on. One claim I remember is an aircraft whose hangar had an ice dam in front of the door. Instead of pulling the aircraft out (since there was lots of ice and he couldn’t get a good footing to pull by hand), the owner decided to “drive” the aircraft out of the hangar. You can probably see where this is going — lots of power to get over the ice and too much power to stop before he hit the other hangars across from him. That did a number on the prop and the other hangar. It’s important to make sure the hangar is ready for cold weather. In a way, it can be almost as important as the aircraft.

This article originally appeared in the October issue of Cessna Owner magazine.