Photo courtesy of Cincinnati Avionics

Last month we discussed engine analyzers. Analyzers have been around for years as a way for pilots to augment factory gauges and, in the process, enhance their “engine situation awareness,” a requirement in my mind for any aircraft heading for the clouds.

Engine analyzers can meet the mission for:

- A well-equipped VFR pilot, especially a VFR pilot who frequently spends much time in mountainous terrain or over water where the “risk” is greater.

- A light IFR pilot who, like most light IFR pilots, flies VFR most of the time and IFR to get away from trouble.

- A light- to medium-IFR pilot on a budget.

- The more serious IFR pilot who often flies for business or who has a lot of IFR experience and is not afraid to dive right in when the weather would keep the less-experienced pilots on the ground.

As I have mentioned before, it’s often budget that keeps a pilot in the VFR or light IFR category. The serious IFR pilot often is not subject to these budget restrictions, which allows them to fly faster, better-equipped aircraft and, let’s face it, the GA avionics industry continues to fuel the desire for a state-of-the-art avionics panel. For this pilot, nothing short of a primary engine management system will do and, fortunately, for the last 10 years or so, that has been the focus of the manufacturers.

A primary engine management system, unlike the analyzer, is designed to replace most or all of the critical engine instruments provided by aircraft manufacturers.

While this can be done with an instrument that fits into an existing panel configuration, most pilots upgrading to “state-of-the-art” choose to redesign and create a new panel for their aircraft. There are two reasons for this. First, the larger format engine management systems simply don’t fit into a factory panel and require a new panel layout. Second, once you have removed all the factory gauges that the primary system replaces with a unit that fits a standard instrument hole, your panel looks like swiss cheese! There are simply not enough little gizmos out there to fill in all these holes, so a new panel becomes necessary.

While this increases the budget, the finished product is amazing and you realize how inefficient factory panels are, especially in a true IFR panel where efficiency matters! Primary engine management options have expanded since we last visited this topic back in 2015. Garmin offered engine management in its G1000 EFIS suite as early as 2004, but it was only available when you bought a new airplane. It is now available in Garmin’s aftermarket EFIS systems or as an individual instrument. We will look at EFIS and the other available primary systems available from Electronics International, Garmin, and JP Instruments listed alphabetically and by budget, as always, to filter out my own bias.

Note: Insight Instrument Corp. was included in the November issue discussion on engine analyzers and is well worth your consideration if you are looking at that market. While Insight offers a few engine parameters in its G series as primary, they fall short of this discussion on primary engine management. Also, in our last discussion on engine management, Ultra Electronics was mentioned. Ultra’s Auracle was the top of the line at the time and the marketing was a bit exclusive. Perhaps a bit too exclusive as this unit is no longer in production.

Electronics International

EI offers the biggest selection of engine instruments. There’s a digital 2 ¼-inch gauge in the EI line for just about any engine parameter you want to add to your panel. In 2009, EI jumped into the large format, primary engine management market with its MVP-50. A turbine version came later. Currently, we have the MVP-50P for aircraft equipped with piston engines (thus the P) and the MVP-50T for turbine equipped aircraft. The MVP-50P is 5.5 inches wide and 5.2 inches tall and could actually fit in a standard radio rack, but what well-equipped aircraft has room there?

As far as covering your engine data, like the spaghetti sauce, “it’s in there”! The MVP-50P monitors (all primary) EGT/CHT (all cylinders), oil temp and pressure, fuel pressure, resistive* fuel level from four tanks, OAT, rpm, manifold pressure, amps, volts, percent of horsepower, and vacuum pressure. It also records engine, flight, and countdown time. It records your flights and allows you to download data through a standard USB port. The MVP-50P uses an engine data converter that mounts on the cockpit side of the firewall. All probes, sensors, and transducers connect to the EDC simplifying the interface to the panel. All that said, the MVP-50P replaces up to 15 instruments and provides up to 50 functions!

MVP-50P pricing online is about $4,700 for a four-cylinder engine and $6,000 for a six-cylinder. With everything that is being connected, expect 40 hours of labor. Most aircraft owners installing an MVP-50P will likely go for a new panel. The alternative would be to install the unit on the co-pilot side, which is less than desirable in my opinion, but as I mentioned before, your engine mechanic is often the more efficient (cost-effective) place to install an instrument like the MVP since the majority of the work is “under the hood.”

In 2013, EI introduced the CGR-30, a compact, primary engine management system that starts by replacing your existing mechanical tachometer and goes on to provide a host of primary and advisory engine monitoring functions in a 3 1/8-inch instrument that seamlessly integrates into your existing panel. With the CGR, there’s no concern about where to put the instrument where it will be most functional because it goes where your existing tach is. Unlike the MVP, which is essentially available in one version, the CGR-30 comes in many versions, consistent with the needs and budget of light and true IFR pilots.

I mentioned the CGR-30 “basic” in last month’s discussion on engine analyzers. The CGR-30P basic provides rpm, EGT/CHT, fuel flow, volts, and OAT as primary plus a number of additional engine parameters as advisory and at $3,000-$3,700 it is affordable, but for this discussion we will focus on the basic’s big brother — the CGR-30P “premium.” The EI CGR-30P premium allows you to choose which parameters you want as primary. RPM, EGT/CHT bar graph, fuel remaining, tach time, local time, fuel used, GPS/fuel flow data, external caution and warning, and data recording are standard features. From there, you choose an additional five parameters: some primary, some advisory like manifold pressure, oil pressure, oil temperature, fuel flow, fuel pressure, right fuel level, left fuel level, aux fuel level, TIT, VAC, and volts. Options also include OAT, horsepower, flight timer, local time, Zulu time, hydraulic pressure, G-meter, carb temp, and amps. The Guardian Avionics remote carbon monoxide sensor is also compatible. The CGR-30P premium has enough available channels to support whatever is essential to you. You’ll find the CGR-30P premium from $3,700 (four cylinders) to $4,200 (six cylinders) plus the additional cost of optional probes and sensors.

Garmin Avionics

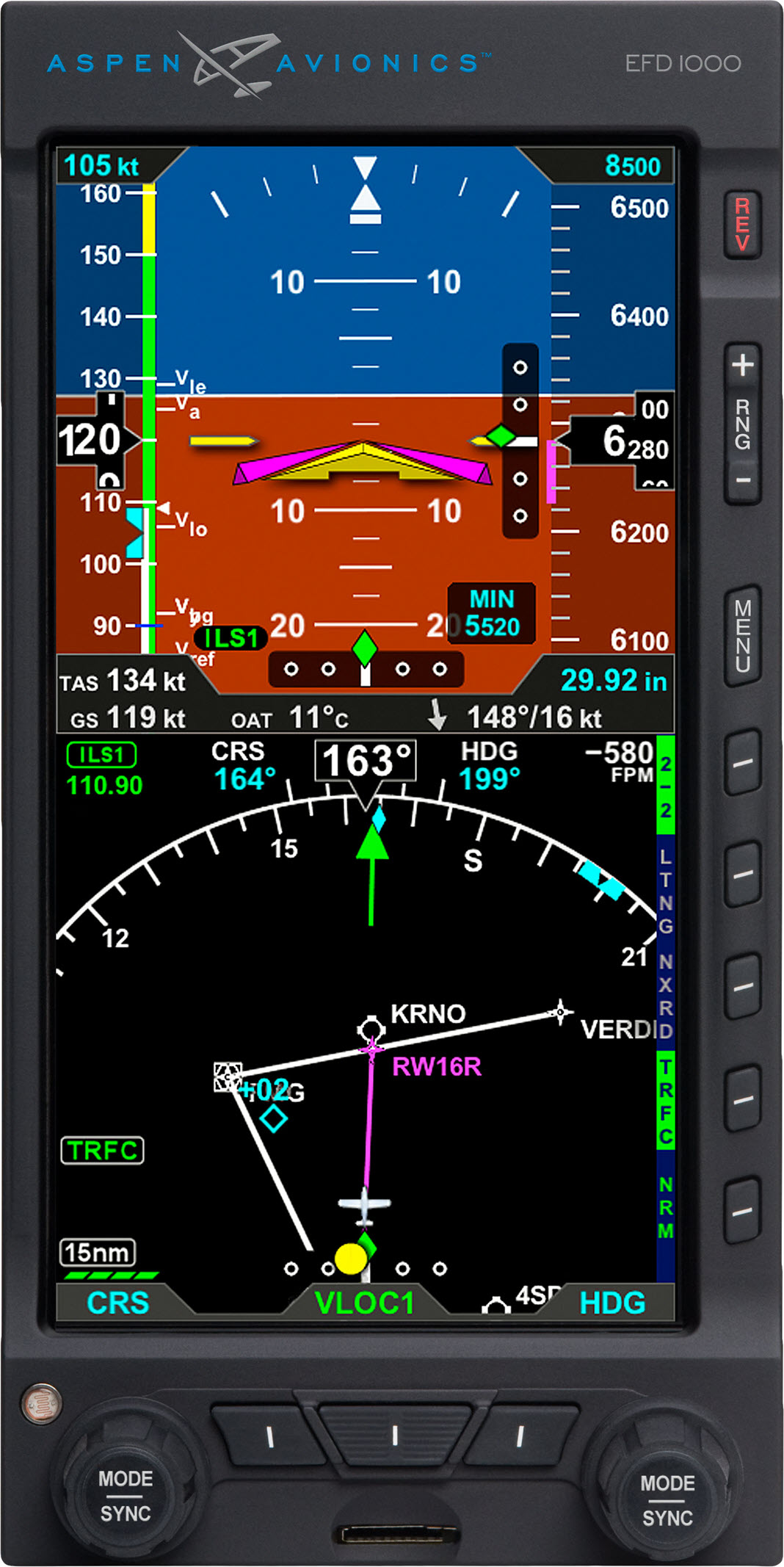

As I mentioned, if you wanted engine data from Garmin, previously it only came as part of the G1000 OEM avionics suite that came with a new airplane. Even the G500 EFIS system introduced in 2009 did not offer engine data. In July 2019, Garmin certified the previously experimental G3X EFIS system for certified aircraft and if you are inclined to add engine management in a larger format than the EI MVP-50 that we have already discussed or JPI’s EDM 930 that we will discuss next, a G3X 7-inch EFIS screen (GDU 470) is the way to accomplish this. Note that the G3X option, versus the G500TXi, will save you money and do the same thing, but at a cost compared to other manufacturers. Plus, while the Garmin EFIS option is more expensive, it gives you less engine parameter coverage. The JPI EDM 930 and the EI MVP-50P replace more instruments and provide more functions.

The G3X 7-inch display with GEA 24 engine module with CHT/EGT, rpm, volt/amps, and fuel level (with compatible sending units) looks like about $10,300 installed, but that does not include additional probes/sensors at an average cost of $225 per sensor for manifold pressure, oil temp and pressure, fuel pressure, carb temp, or OAT. Fuel flow alone is $500, plus you have the additional labor on these options, making it impossible to give you a final installed cost here.

In 2020, Garmin introduced the GI 275 electronic flight instrument. The previous G5’s AI and HSI had no provision for engine data but the GI 275 can serve many roles including that of a 3 1/8-inch engine management system. You start with the GI 275 basic, add the GEA 24 engine module ($3,995 for both), and add the EIS sensor kit ($900 for four-cylinder, $1,300 for six-cylinder).

This gives you sensors for EGT/CHT and oil pressure, but oil temp and manifold pressure are required. These will run about $225 each and, like the G3X, fuel flow and pressure are almost a must and that is another $725-ish. Add the additional sensors and probes you want, some that Garmin does not sell (you find them from independent sources) and, as you can see, it’s not only a more expensive way to go but a little more work than a system from EI or JPI that comes as a more complete package. The bottom line on engine management is that EI and JPI are “passionate” competitors and their pricing reflects it. You’ll frequently find rebates available from these companies that even Garmin cannot compete against.

JP Instruments

In last month’s discussion on engine analyzers, I mentioned the JPI EDM 830 as a shining example of an advisory analyzer that could even be used by a true IFR pilot on a budget — it does that much. For the pilot with the budget and the desire to replace mechanical gauges with digital accuracy, JPI offers two models with primary certification that meet the mission: the newer EDM 900 or the well-established EDM 930. JPI recognizes that there are two markets here. For the pilot/owner who already has the avionics suite they need and is just adding engine management, the EDM 900 fits nicely into an existing panel and gives this pilot all the information they want. The EDM 900 mounts in a standard 3 1/8-inch hole and, because all functions are certified as primary, it allows you to remove your old analog gauges. We are no longer just talking about an analyzer, but rather an engine management system or, as JPI likes to call it, “your personal on-board flight engineer!”

The EDM 900 does it in a compact unit with too many features and benefits to list here and it is designed for the pilot who already has the avionics panel he or she wants or as an element in a new panel layout. You’ll find the EDM 900 at about $3,900 for four-cylinder engines or $4,300 for six cylinders, but the system can also monitor fuel level (including standard capacitive systems). You add about $200 for a two-tank system or $400 for an aircraft with four tanks.

The EDM 930, on the other hand, is frequently the choice for pilots who are engaged in a complete avionics panel upgrade and who are designing/building a new panel. Pilots in “true” IFR conditions want and need a lot of information in front of them. The EDM 930’s larger form factor delivers this information in a format that’s easier to read and interpret quickly. All parameters are certified primary, so all the old stuff comes out and is replaced by the EDM 930. As with the 900, there is just too much in the 930 to list here. For twin flyers, the answer is the EDM 960 twin-engine management system. As above, the list of gauges it replaces and the number of functions is extensive so check the links in the sidebar of this article for the details. You’ll find the EDM 930 in a four-cylinder version at about $5,500 and $5,700 for the six-cylinder version, and as with the 900, the 930 can monitor your fuel tanks (capacitive or resistance) for an additional $200-$400.

Conclusion

“Situation awareness” are words we often use in aviation. When we consider the tools we had to fly true IFR 40 years ago compared to today, it is amazing how much progress we have made. Knowing where you are and what is going on around you has changed significantly!

What used to involve calculating the intersection of two VOR radials and applying that to the chart on our lap, is today replaced by WAAS-corrected GPS units that tell us exactly where we are within 7 feet.

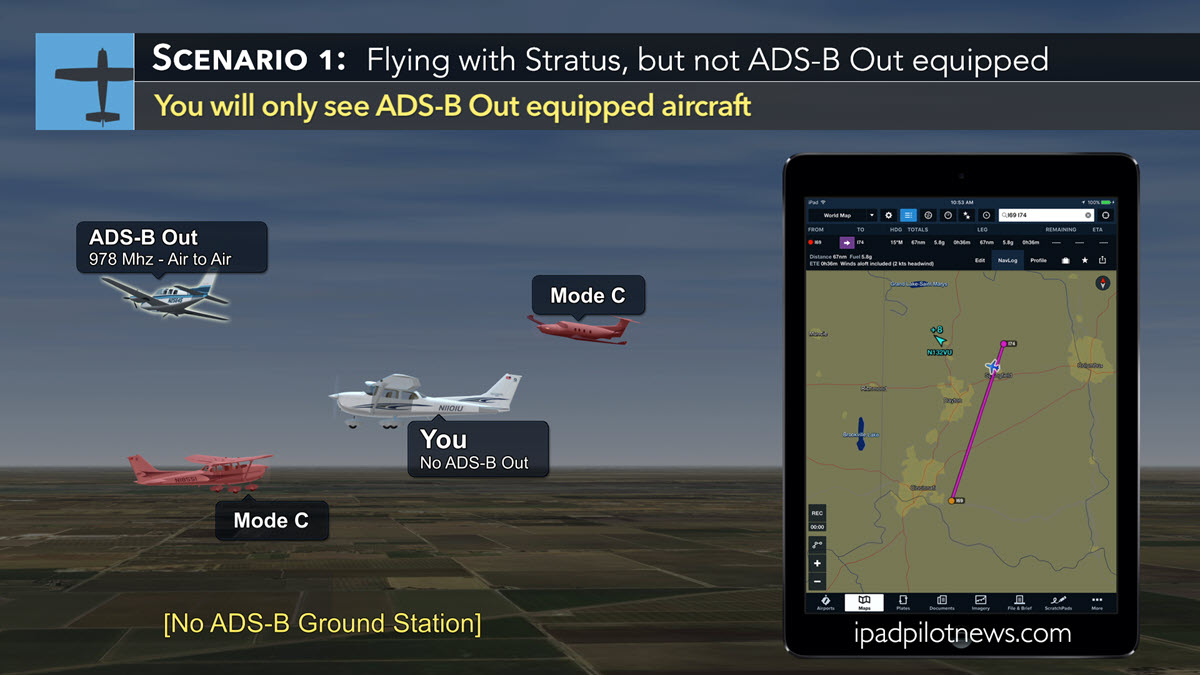

We used to depend on ATC to warn us of other aircraft in our vicinity, but today ADS-B tells us directly, actively warns us of the threat, and shows us the traffic on a map. We used to depend on the limited engine information we got from aircraft manufacturers to know the condition of our engine in IFR flight. Today, with a sophisticated engine management system on board, you know exactly what is going on with your engine “right now” and since these systems are interactive, they tap you on the shoulder and tell you when something is not right.

Our situation awareness has never been higher thanks to the tools that we have available now and pilot load and stress has been significantly reduced. Not all of it, though. You still have to worry about how you’re going to pay for all this stuff!

Until next time … safe and happy flying!