Carbon monoxide (CO) has been a potential safety issue for the GA community for as long as we have had combustion engines and enclosed cockpits. The Red Baron had no concerns about carbon monoxide. He was worried about lead — which ultimately led to his death in 1918 over France by Allied gunfire. For years, the GA community downplayed the risk of CO. Prior to 2001, the way you attempted to protect yourself from CO was to put a CO detector “patch” on it.

When I covered CO in the April 2017 issue, I featured Guardian Avionics, which first brought an alternative to the patch and introduced active technology to protect yourself from CO. Now, we see other manufacturers recognizing that CO can be a problem and incorporating CO detection technology into their products. It seems we have something new to talk about. Let’s start with some facts and stories about CO and what can go wrong when it finds its way into your cockpit.

CO in the Cockpit

Most seasoned pilots know this story — and it’s absolutely true. On a clear, bright morning in 1998, Dr. Robert Frayser took off from a Kansas airport enroute to Topeka in his Piper Comanche 400. Everything was hunky-dory. Dr. Frayser remembers changing fuel tanks but not much else after that. The aircraft was pointed toward his destination, and he was cruising comfortably on autopilot. An hour and a half later, he woke up on the ground. His wrist was broken, and his plane was a mess, but he was alive.

Dr. Frayser was quoted as saying that he had no warning: “I just went to sleep.” The aircraft continued to fly beyond his destination into Missouri where, once its fuel was exhausted, it maintained a controlled descent, courtesy of the Century autopilot (with Autotrim, I believe), into a field. Century Flight Systems later used the incident as an opportunity to promote the safety of their autopilots in a sort of “Hey, my Century autopilot saved my life!” campaign. (You can find an FAA article about the incident by searching the article’s title, “An ‘Unconscious’ Landing.”)

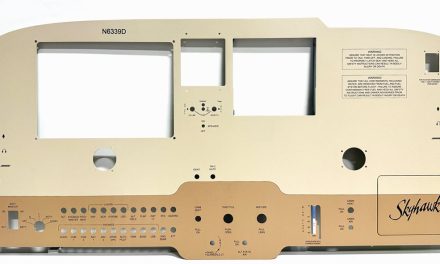

The 400 is a pretty rare bird and about the only single-engine airplane I know of that offered an eight-cylinder engine. You might say it was the muscle car of GA singles in 1998. Ironically, I just helped my fourth client with a panel upgrade in their Comanche 400. An inspection of the aircraft’s Lycoming engine revealed that a crack had opened up some time after the aircraft’s annual inspection, and this crack was hidden by the heat exchanger. I suspect that Dr. Frayser used his heater on that early morning flight — just as any pilot would. But in doing so, he unknowingly invited a dangerous amount of carbon monoxide (CO) into the cabin and was overcome by its effects. After the incident, 20 other aircraft at Dr. Frayser’s home airport were inspected. Three were found to have exhaust leaks and only two of the 20 were equipped with CO detectors.

If you’re thinking this is only a Piper problem, read on. In December 1997, a brand-new Cessna 182S left the factory and was being ferried to its new German owner. Feeling ill, the ferry pilot suspected carbon monoxide exposure and safely landed the aircraft. An inspection of the aircraft’s exhaust system found faulty welds. Moreover, a subsequent inspection by Cessna using pressure tests found that 20% of the 172 mufflers they had in stock suffered from the same faulty welding problem!

There are many stories like this. For instance, also in 1997, an instrument-rated pilot took off from Long Island with his 71-year-old mother for a flight upstate. The Pilot in Command (POC) of the Piper Dakota passed out 30 minutes into the flight, and his mother — with her low-time private ticket — took over. She contacted Air Traffic Control but reported feeling tired and nauseous 10 minutes later. Shortly thereafter, the plane turned right and started to climb before it ultimately crashed in New Hampshire. CO had done it again!

A week after the Dakota crash, the AOPA Air Safety Foundation (ASF) issued a warning to pilots about CO and recommended the installation of CO detectors in the cockpit. Surprisingly, however, the Executive Director of the ASF suggested that this was a rare occurrence and pointed to only two cases (in the ASF database) in which CO was the cause of a crash between 1985 and 1994. But the ASF data was wrong! There were more than a dozen CO-related accidents during that period. Bottom line: Although rare, CO was killing pilots.

Twenty-five years later, Guardian Avionics is, in my opinion, still the aviation leader in active CO detection, but uAvionix/ ForeFlight and Lightspeed have recently incorporated active CO detection into their products too. Before we look at their products, let’s discuss the “patch.”

Unfortunately, the technology to detect CO in an airplane was primitive and passive in 1999, as the stick-on “patch” was about the only available option. I’ve owned six airplanes, and some had one of these on the panel. I never really understood them, nor was I ever trained to include it in my normal instrument scan.

Moreover, most of the patch-type CO detectors are only effective for 90 days! Did you know that? On top of that, they often cannot detect smaller concentrations of CO, and they’re easily contaminated by exposure to commonly used cleaning products. You’ll find the “patch” available online from $4 to $10. We’ve talked about active vs. passive warning devices. This again proves that, in most situations, the passive approach simply doesn’t cut it! If you’re depending on the patch to protect you from CO, you’re selling yourself short.

The rest of this article can be seen only by paid members who are logged in.Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

JOIN HERE

Still have questions? Contact us here.