Stress corrosion cracking is usually preceded by visible corrosion on the fitting. Any corrosion visible in the area of the fitting is cause for concern.

The FAA issued a special airworthiness bulletin (SAIB) on July 2 advising owners of all aircraft to check for corrosion cracking on flight control cable attachments connected to turnbuckle barrels during their next annual or general inspection. At this time, the FAA states that the concern does not warrant airworthiness directive (AD) action and that it does not expect failures to occur on parts with less than 15 years’ time in service.

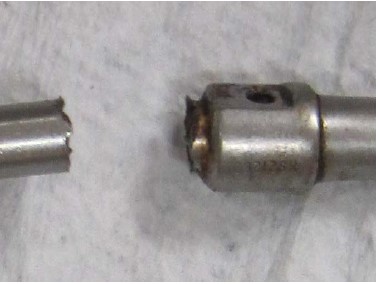

The bulletin comes following numerous reports of failures of the cable/turnbuckle attachment fittings, which have caused or have the potential to cause loss of flight control in one axis. In most incidents, the pilot was able to land the airplane without damage, but accidents with substantial damage have occurred in some cases.

Exposure to contamination (chlorides) and sustained tensile stress are the major risk factors with heat also a contributing factor. Corrosion cracking and fracturing is therefore likely to occur more quickly in a warm, humid, salt air environment, and progresses based on calendar time rather than flight time.

The SAIB action items read as follows:

- Upon any annual or other general inspection of the flight control cables, carefully examine all cable terminal fittings that attach to all turnbuckles for corrosion and/or cracking (in addition to inspecting the turnbuckles and the entire length of the cables as you normally would).

- If no corrosion or cracking is present:

-

-

- Apply a corrosion preventative to the swaged fittings if recommended by the manufacturer.

- Replace any removed safety wire with new safety wire in accordance with normal procedures.

-

- If any sign of corrosion, pitting or cracking is present on any fitting, replacement of the associated fitting and/or cable assembly is recommended.

- For those airplanes with a history of significant exposure to warm, humid, salt air environments, replacement of all primary flight control cables that have been in service for 15 years or longer is recommended. Additionally, replacement of any cable that has a turnbuckle fitting located in an area of the airplane subject to elevated temperatures, the prevalence of condensation, or in close proximity to the airplane battery, and has been in service for 15 years or longer is recommended.

To read the entire SAIB including complete instructions for inspection, click here.

Failure of a flight control cable terminal attachment fitting.