Most STC installation manuals instruct you to use standard calibration, draining the fuel tanks and adding measured fuel in steps while recording the fuel sender output for each, to your tanks. However, reverse calibration, starting with full tanks and draining them in known increments, is a more accurate way to test bladder-style tanks because:

- They are flexible and do not deform uniformly when being filled and emptied

- The resulting calibration curve can appear flat near empty, under-reporting fuel.

- Top-end accuracy is difficult to trust, especially with aging or misshaped bladders.

By starting with a full tank and draining fuel in steps, the tank collapses naturally — and the sender readings more accurately reflect real-world conditions. Among the aircraft that benefit from this method are early single-engine Cessnas with bladder-style mains and Cessna twin-engines with auxiliary tanks.

FAA regulations like 14 CFR 25.1553 and legacy § 23.959 do require accurate, usable fuel quantity indication, but they do not specify whether calibration must be performed from empty to full. This allows room for shops to use their discretion about how data is collected, as long as the stored calibration points are entered in the proper order.

How to Do a Reverse Method Calibration

(While staying within installation and FAA guidelines and compliance)

Reverse Data Capture:

- Fill the tank completely

- Drain in precise steps (e.g., 5-gallon intervals)

- Record fuel quantity removed and sender output at each point

- Use your EFIS or engine monitor to log raw frequency

- Maintain aircraft in level flight attitude

Feed the Data (In Compliance):

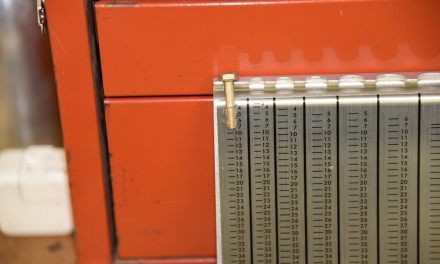

- Use a precision frequency signal generator to inject the recorded frequency values back into the instrument

- Perform the standard empty-to-full calibration, matching your signal injection to fuel levels at each step. Your data should match actual tank behavior.

Once completed:

- Your data matches actual tank behavior.

- The calibration order complies with STC guidance.

- Your accuracy is significantly improved.

Double-Check Accuracy Before Sign-Off.

Once the system is calibrated:

- Fill each tank completely

- Confirm that each fuel display reads at or near full capacity, within 1–2 gallons

- Then drain each tank partially, and confirm known volumes are reflected in the gauge readouts at midpoints (e.g., half tank, quarter tank)

- If discrepancies exceed acceptable tolerance (typically 2–5%), revisit the associated calibration points

This extra validation ensures that the display reflects real fuel quantity, not just the shape of a curve.

Recommendations

These two generators are proven, budget-friendly tools to help you simulate CiES sender output during instrument calibration:

- FeelTech FY3224S Function Generator

- JDS6600 Signal Generator

Conclusion

Reverse calibration isn’t a loophole. It’s a smart response to real-world tank behavior, especially in bladder-equipped aircraft. As long as you are careful to do it properly, you will stay within the spirit and structure of FAA guidance.

Information in this article is taken from “Rethinking Fuel Tank Calibration” by Daniel Alm. With over eight years of experience solving installation and technical issues in the aviation industry, Alm is a vital member of the CiES Support Team. He is a trusted resource for aviation mechanics and technicians with a simple mission: to deliver clear, effective support that keeps aircraft and teams flying safely and smoothly.

CiES Incorporated is an innovative engineering and manufacturing company specializing in high-precision fuel level sensing technology for the general aviation industry, headquartered in Bend, Oregon. CiES is best known for its patented, state-of-the-art digital fuel quantity systems, which offer enhanced accuracy, reliability, and safety over traditional analog systems. Visit their website at www.ciescorp.net or call (541) 977-1043.