Combat the Oft-ignored Dangers of Airframe and Engine Vibration with Cessna Propeller Dynamic Balancing

By Matthew Dock, RPX Technologies

The worst thing about complacency is that you don’t know it is happening.

We’re conditioned to ignore what is “normal” and only worry about things that change.

As a pilot who has flown a 1963 Cessna 150 from the Bahamas on the east coast to the Channel Islands on the west coast, I know that I’m relaxed as long as the sound and feel of the engine doesn’t change. On the other hand, any variation in RPM or vibration will immediately cause me to jump. Unfortunately, even though most damage is related to fatigue caused by the constant vibration of metal (and people), we’re “tuned” for change—not the constant drone of engine and propeller.

Pilots and passengers are also very susceptible to fatigue from aircraft vibration. In fact, the military has done numerous studies on the impact of vibration on the human body. The whole body vibration frequency is approximately 4-8 Hz, or 240-480 RPM. This is one reason that helicopter pilots often complain about back problems; the whole-body vibration matches closely with the main-rotor blade rotation frequency. For small piston engine aircraft operating at 2400 RPM, this causes a 40Hz vibration. That 40Hz vibration causes fatigue in the lighter portions of the body, like the hands, feet, and eyes. The vibration often causes numbness or tingling, usually in the feet due to the proximity to the firewall. After measuring excessive vibration on an engine, I’ll often ask pilots about their feet becoming numb or their eyes being fatigued from monitoring a shaking instrument panel.

While pilot and passenger vibration is tiring, airframe vibration can be dangerous. Excessive engine vibration can lead to a broad series of failures that often appear unrelated. Exhaust cracks are one case in point. An engine vibration near the FAA limit of 1.2 inches per second (AC 20-37E) can easily generate displacements of 0.060 of an inch. That doesn’t seem like much, but imagine an exhaust pipe that is held at one end and then shaken at 0.060″ at 40 Hz for hundreds of hours. All the weld joints and sharp bends will experience high stresses as the unsupported weight of the exhaust works against the vibration. This high stress causes fatigue cracks that lead to failure of the exhaust system, spilling exhaust air into the cowling and possibly the passenger compartment. This is one reason that high-end exhaust manufacturers require dynamic balancing for their warranties. At best you need a new exhaust, at worst you experience hypoxia due to the fresh air inlet being positioned directly behind the cracked exhaust pipe—like I did in my Cessna 150.

Cessna Propeller Vibration Costs Money

That cracked muffler on a simple Cessna 150 can cost hundreds of dollars to repair or replace, plus the cost of disassembly and assembly. Other vibration induced failures can be equally expensive. The panels of older aircraft contain numerous electrical and vacuum-operated gyros that operate on small bearings. Bearing life is reduced by the third power of acceleration. This means that for every 10X increase in vibration, there is a 1000X reduction in bearing life. Just the directional gyro or artificial horizon in a Cessna 150 can cost thousands if purchased new.

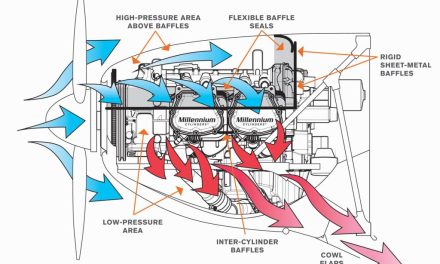

Although most props are statically balanced at the factory, once installed on an aircraft vibration is induced by imbalance and the slightest misalignment of any part of the rotating assembly. This includes the spinner, propeller, prop mounting hardware, starter ring, crank, and everything else that rotates when the engine is running. Even the slightest mass imbalance in any of these components can be felt throughout the aircraft and puts an enormous strain on the engine and instrumentation. To correct these vibrations, the entire assembly must be dynamically balanced.

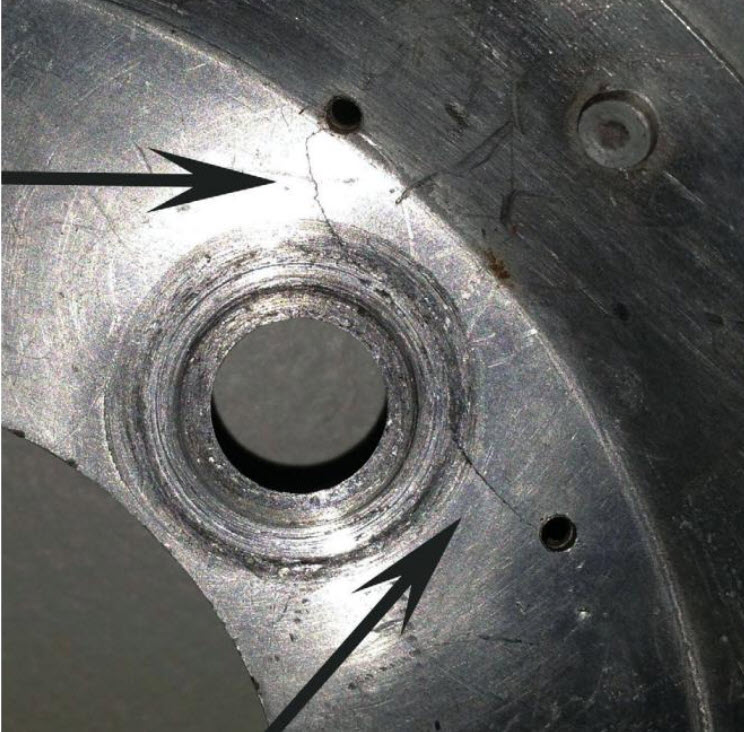

In addition to exhaust and panel issues, there are engine mount and firewall cracks which may also lead to costly repairs. The spinner and spinner back-plate take a lot of abuse as well. The repair or replacement costs of these components can add up significantly over the life of an aircraft. Fortunately, the life of all these components can be improved by first locating the cause of the vibration and then reducing it.

More Cessna Research

New-to-You Cessna: Your First 4 Steps

How to Reduce Vibration: Cessna Propeller Dynamic Balancing

The best way to reduce airframe vibration is to have the airplane dynamically balanced. Good dynamic balancing will have multiple steps that provide the owner/operator with a smooth aircraft. Any dynamic balancing service will start with a good pre-balance inspection that addresses the items previously listed. After inspection, the mechanic will install an accelerometer and a phototach to measure the vibration and the position of the propeller. The mechanic will run the engine three or more times to add weight and reduce the vibration. Dynamic balancing is typically a simple, straightforward process. If difficulties are encountered it may be due to loose equipment or damaged components, something that should be addressed immediately. Ask your mechanic about getting your aircraft dynamically balanced.

The DynaVibe Classic is a cost-effective solution to the largest contributor of aircraft-damaging vibration – propeller imbalance. The DynaVibe Classic prop balancer tells you how out-of-balance the prop is (magnitude), and where adjustments are needed (phase/angle). The complete kit costs $1,495 and includes everything you need to get started: Meter, Accelerometer, Optical Tach, Reflective tape, Instruction Manual, and Carrying Case. Note: Each engine type requires an easily fabricated sensor mounting bracket.

FAQ

Who can perform Cessna propeller dynamic balancing?

For certified aircraft, when following FAA-approved procedures, dynamic balancing is performed by an “appropriately rated mechanic,” a power plant mechanic.

Is dynamic balancing a major repair?

Dynamic balancing is a not a major repair when using FAA-approved procedures.

FAA Advisory Circular 20-37e, Aircraft Propeller Maintenance, is a great resource for information. It discusses dynamic balancing and general maintenance procedures for aircraft. For more information, visit www.rpxtech.com.

Top 10 things to check when experiencing vibration:

- Spinner Imbalance – Run the engine with the spinner off and see if the vibration changes. A lot of spinners are out-of-balance and will cause damage to the spinner back-plate.

- Blade Track – Pull the sparkplugs so the engine will freely rotate. Use a fixed object on the floor to check that all the blades are within 1/16 of an inch.

- Blade Pitch – There are inexpensive digital protractors that will allow you to measure the pitch of the blade; usually best done at multiple locations along the blade.

- Compression – Check the differential cylinder compressions for any weak or leaking cylinders.

- Intake Leaks – Check for intake leaks that may cause one cylinder to run lean and misfire.

- Ignition System – An old magneto or fouled plugs may provide a weak spark, causing poor ignition.

- Engine Mounts – Damaged or compressed motor mounts can transmit additional vibration. Also verify the installation of the motor mounts. Different engine/airframe combinations may require a very specific installation.

- Wheel Pants – This may sound odd, but sometimes the wheel pants or other loose accessories can start to vibrate in-flight, causing airframe vibration.

- Engine/Cowling Contact – The engine, exhaust, intake, and all other components mounted to the engine should be free and clear of contact on the cowling. Look for rub marks on the inside of the cowling.

- Check the Dynamic Balance – Even a statically-balanced propeller can generate significant vibration, just from the installation variations. Dynamic balancing should be done often to ensure smooth flying.

This article was written by DynaVibe. Learn more here.